Supplier Quality Assurance for Circuit Board Printing

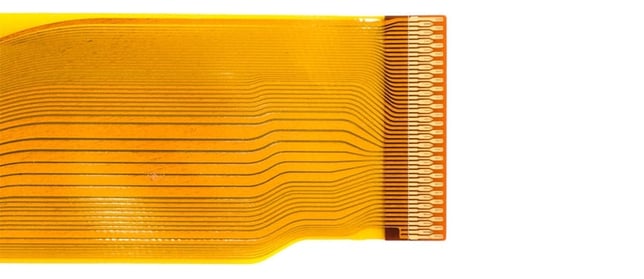

Key Takeaways Supplier changes can introduce subtle surface-related risks that traditional quality checks may not detect Circuit board printing on polyimide film is highly sensitive to surface cleanliness and consistency Without objective surface specifications, supplier quality expectations can...

Read

Topics:

Posts by Topic

New Surface Quality Measurement Method Improves Vendor Compliance

Key Takeaways: Kala replaced imprecise dyne pens with Brighton Science's Surface Analyst technology to improve vendor compliance and surface quality control. They identified and documented microscopic surface energy inconsistencies in supplier film, leading to rapid vendor response and over...

Read

Topics:

Monitoring the Application of a Barrier Coating on the Inside of Paint Cans

Key Takeaways Barrier coatings inside paint cans play a critical role in preventing corrosion, leaks, and paint defects like skinning. Traditional benchtop measurement tools struggled with textured, hard-to-reach surfaces and factory floor constraints. Handheld surface energy measurements enabled...

Read

Topics:

Identification of a Non-Obvious Contaminant on Polymer Film

Key Takeaways A major packaging manufacturer was experiencing intermittent heat seal failures on a polymer film that should have behaved consistently. Dyne pens showed no difference between good film and bad film, which initially misled the team. Brighton Science identified a subtle contaminant...

Read

Topics: