Beauty and Wonder from the Macro to the Micro

Key Takeaways Small observations reveal big insights: Even tiny phenomena, like a few saltwater droplets on a tablecloth, can illustrate fundamental chemical principles such as deliquescence and surface tension. Surface chemistry governs real-world behavior: Dissolved salts increase water’s...

Read

Topics:

Posts by Topic

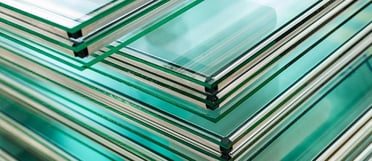

Window Manufacturers Evolve from Dyne Inks to the Surface Analyst

Key Takeaways A window and door manufacturer needed a more objective, non-destructive way to verify plasma treatment. Dyne inks created challenges due to mess, subjectivity, and part damage. Transitioning away from dyne required maintaining dyne-based language for suppliers and customers. The...

Read

Topics:

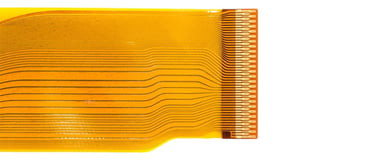

Supplier Quality Assurance for Circuit Board Printing

Key Takeaways Supplier changes can introduce subtle surface-related risks that traditional quality checks may not detect Circuit board printing on polyimide film is highly sensitive to surface cleanliness and consistency Without objective surface specifications, supplier quality expectations can...

Read

Topics:

New Surface Quality Measurement Method Improves Vendor Compliance

Key Takeaways: Kala replaced imprecise dyne pens with Brighton Science's Surface Analyst technology to improve vendor compliance and surface quality control. They identified and documented microscopic surface energy inconsistencies in supplier film, leading to rapid vendor response and over...

Read

Topics:

Verifying Multi-Step Surface Preparation Processes in Aircraft Assembly and Repair

Key Takeaways Verification at every step is essential. Multi-stage surface preparation workflows in aircraft assembly and repair require stepwise validation to ensure each action contributes to a bond-ready surface. Unexpected contamination can originate within the process itself. In this case, a...

Read

Topics:

Monitoring the Application of a Barrier Coating on the Inside of Paint Cans

Key Takeaways Barrier coatings inside paint cans play a critical role in preventing corrosion, leaks, and paint defects like skinning. Traditional benchtop measurement tools struggled with textured, hard-to-reach surfaces and factory floor constraints. Handheld surface energy measurements enabled...

Read

Topics:

Optimizing Parts Washer Efficiency for FIPG

Key Takeaways The reliability of formed-in-place gaskets (FIPG) depends heavily on surface cleanliness before sealant application. Automotive manufacturers often struggle to verify and control industrial parts washer performance, creating risks for leaks, failures, and costly rework. Objective...

Read

Topics:

Identification of a Non-Obvious Contaminant on Polymer Film

Key Takeaways A major packaging manufacturer was experiencing intermittent heat seal failures on a polymer film that should have behaved consistently. Dyne pens showed no difference between good film and bad film, which initially misled the team. Brighton Science identified a subtle contaminant...

Read

Topics:

How NKT Photonics Eliminated Bond Failures with Surface Intelligence

Challenge When NKT Photonics was forced to internalize its aluminum etching and surface preparation processes after losing a supplier, the transition led to unexpected bond failures. Despite duplicating the equipment and processes, the failures persisted, resulting in significant financial loss and...

Read

Topics:

Bonding Composites: Confirming Surface Readiness with Reliable In-line Assessment

An aerospace spacecraft manufacturer uses the Handheld Surface Analyst 5001 to confirm surface readiness.

Read

Topics:

When the Success of a Bond Influences a Life: Prosthetic Attachment

Ensuring a bond will hold is the most important component of adhesion. At times, a successful bond could change a life.

Read

Topics:

Verifying and Monitoring Surface Preparation Processes of Golf Club Manufacturing

Key Takeaways High contact angles after grit-blasting indicate a surface preparation failure, not necessarily an instrument issue. Surface energy measurement verifies grit-blasting effectiveness in real time, before bonding failures occur. Contaminated or worn grit-blast media can deposit...

Read

Topics:

Reevaluating the Assembly Process of Failing Oil Filters

When manufacturers supply products to customers, they want to have the highest confidence in the quality of those products. But, when proper measures aren't accessible or available to guarantee quality, a major need arises.

Read

Topics:

Incoming: Validating Supplier Materials for Solar Panel Manufacturing

When manufacturers experience difficulties relating to product quality, it's common to believe the issue to be internal, and this is sometimes the case.

Read

Topics: