Supplier Quality Assurance for Circuit Board Printing

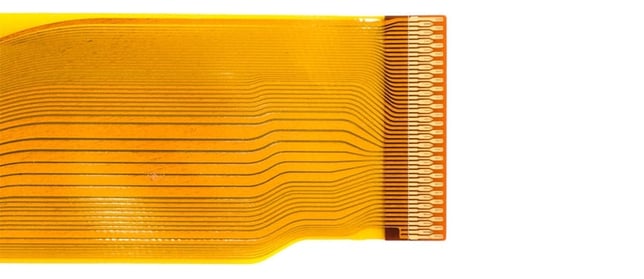

Key Takeaways Supplier changes can introduce subtle surface-related risks that traditional quality checks may not detect Circuit board printing on polyimide film is highly sensitive to surface cleanliness and consistency Without objective surface specifications, supplier quality expectations can...

Read

Topics:

Posts by Topic

New Surface Quality Measurement Method Improves Vendor Compliance

Key Takeaways: Kala replaced imprecise dyne pens with Brighton Science's Surface Analyst technology to improve vendor compliance and surface quality control. They identified and documented microscopic surface energy inconsistencies in supplier film, leading to rapid vendor response and over...

Read

Topics:

Verifying Multi-Step Surface Preparation Processes in Aircraft Assembly and Repair

Key Takeaways Verification at every step is essential. Multi-stage surface preparation workflows in aircraft assembly and repair require stepwise validation to ensure each action contributes to a bond-ready surface. Unexpected contamination can originate within the process itself. In this case, a...

Read

Topics:

Optimizing Parts Washer Efficiency for FIPG

Key Takeaways The reliability of formed-in-place gaskets (FIPG) depends heavily on surface cleanliness before sealant application. Automotive manufacturers often struggle to verify and control industrial parts washer performance, creating risks for leaks, failures, and costly rework. Objective...

Read

Topics: