Manufacturers have numerous options at their disposal when it comes to preventing product failures resulting from imperfect adhesive bonding. Often, the approach is to simply accept adhesive bonding failures as part of the scrap rate and move on. In other cases, companies may completely revamp their production system without ever identifying the root cause.

There are many ineffective approaches to achieving a failure rate of zero. To truly address adhesive bonding failure, a different perspective is required. Most methods of remedying adhesive bonding failures start by searching in the wrong areas. Understanding where to look stems from understanding the actual causes of adhesion failures.

What is Adhesive Bonding?

Adhesive Bonding is the process by which two surfaces are joined together utilizing the intermolecular attractions between the surfaces and an intermediate substance (adhesive).

Adhesive bonding has revolutionized product design by streamlining the process and utilizing only three components - two substrates, bonding materials, and adhesive material. This innovation eliminates the need for excessive fabrication, resulting in greater efficiency and cost-effectiveness. Adhesively bonded joints offer enhanced durability, resilience, and reliability compared to traditional methods that rely on heavy metal fasteners. Unlike welding or mechanical fasteners, adhesive bonding is particularly effective when joining dissimilar materials. It ensures a durable bond strength and eliminates the need for additional equipment and cleaning operations, making it a game-changer in product design.

Adhesive bonding is a chemical synthesis process. Using fasteners is a purely mechanical operation. When we add an adhesive to a substrate and then cure it, this often involves chemical reactions to the adhesive. The top few molecular layers of the substrate’s surface immediately interact with the top few molecular layers of the adhesives. They chemically bond through the attraction of the molecules present there. These sorts of changes and reactions don’t factor into using a mechanical fastener. Surface intelligence allows us to understand this chemical process and the effect the entire production process has on our ability to create predictably resilient adhesive bonds.

Read more about the differences between adhesive bonding and mechanical fastening in this blog post.

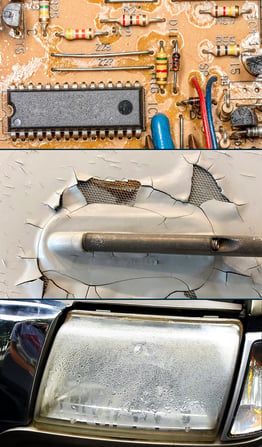

When we talk about adhesive bonding failures in manufacturing, we’re talking about examples like:

- Delamination of circuit board coatings and shorts in connections

- Automotive engine or transmission seals leaking

- Medical tubing not being uniformly coated or appropriately lubricious

- Structural glass panels not fully insulating a building

- Ink coming off food and medicine labels

- Aircraft adhesive fasteners failing

- Medical diagnostic devices with poor coatings

- Composite bonding failure

- Plastic packaging unsealing

- Automotive recalls due to steering column electronics malfunctioning

- Moisture getting into lighting fixtures

- And on and on

These failures seem pretty distinct from each other and span many industries, but they all have one thing in common - a bond did not hold as expected.

So, no matter what kind of manufacturing process a business is using, there are principles that can lead them to the root cause of adhesive bonding issues to prevent them from occurring in the first place or to put a stop to ones that already exist.

Rethink your adhesion manufacturing processes with Surface Intelligence.

Knowing Where to Look for the Root Cause

One of the first hurdles manufacturers run into is when they begin investigating the origins of adhesive bonding problems; they only look at the adhesive joint or the material. Now, this can tell you a lot, but it’s only the beginning of the story. Examining the failure in adhesive bonding provides insights into the specific location of the failure within the material system. If the substrate is experiencing breakage or the adhesive is deteriorating, it may be necessary to substitute them with more robust and suitable alternatives for the particular application.

If the failure is occurring at the interface of the bond, then most manufacturers will rightly assume that this is probably a cleaning issue. To solve the problem, though, they will blindly add cleaning or surface treatment steps, hoping that the adhesive bonding issue is taken care of. It is reasonable to assume that if a surface is not clean and there is already equipment being utilized for surface preparation to clean and treat the materials, then it would be practical to send the unclean parts back through these processes. That would be a great solution if it is definitively known that the root cause of the failure is contamination that can be removed by these cleaning and surface treatment processes.

However, in our extensive experience assisting some of the world’s largest manufacturers, we have discovered that adhesion problems are often far more complex than manufacturers initially believe.

Go Back to the Beginning

The best way to get to the source of adhesive bonding issues, even if you’re still in the New Product Development stage, is to go all the way upstream.

The truth is, joining techniques and bonding processes are much more involved than just the obvious steps where surface manipulation and bonding operations take place. The adhesion process spans the full life of all materials involved in the application. This includes what occurs before the parts and components even enter the production facility.

The surface of the material is where adhesion takes place, and therefore, understanding and controlling the surface quality at every stage of the process is critical to having the ability to accurately predict success. Creating a process map can help break down your process and take a closer look.

When manufacturers continuously measure and monitor the incoming surface quality of their components, they can immediately detect outliers and take action before the material is processed.

Get the Full Scope

When exploring the provenance of contamination or other destructive factors that are leading to adhesion failure, it is important not to rule anything out without truly investigating.

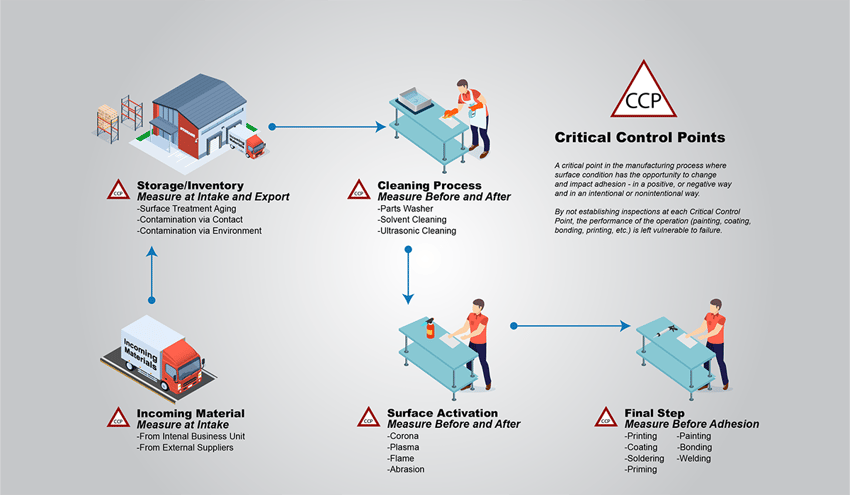

There are Critical Control Points that need to be precisely inspected and scrutinized because these are areas where the surface has even just the opportunity of changing.

Intentional changes to the surface could be:

- Parts washers

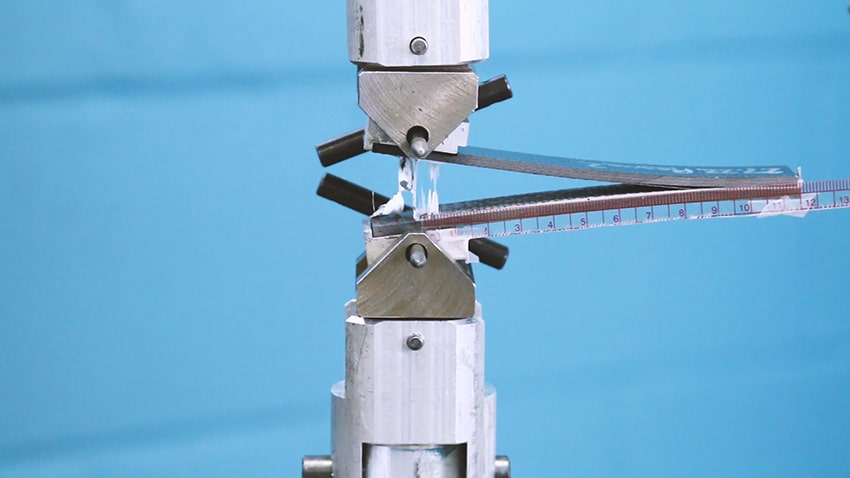

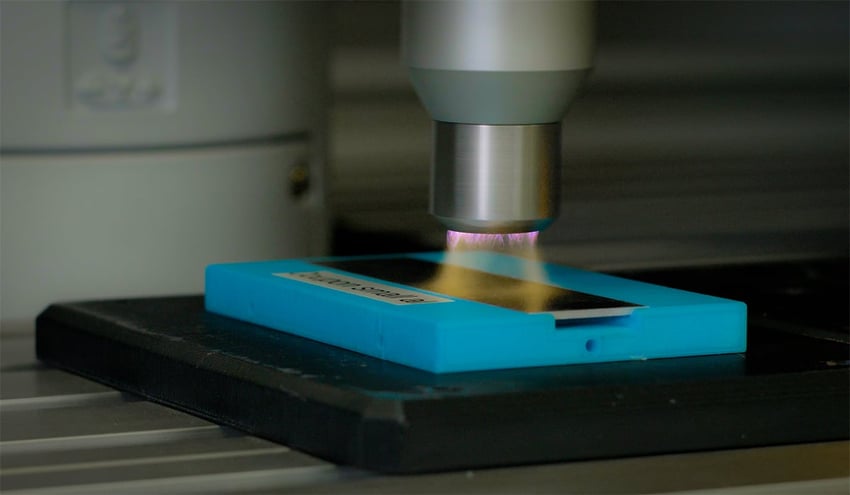

- Pretreatment processes like plasma treatment, corona treatment, or flame treatments

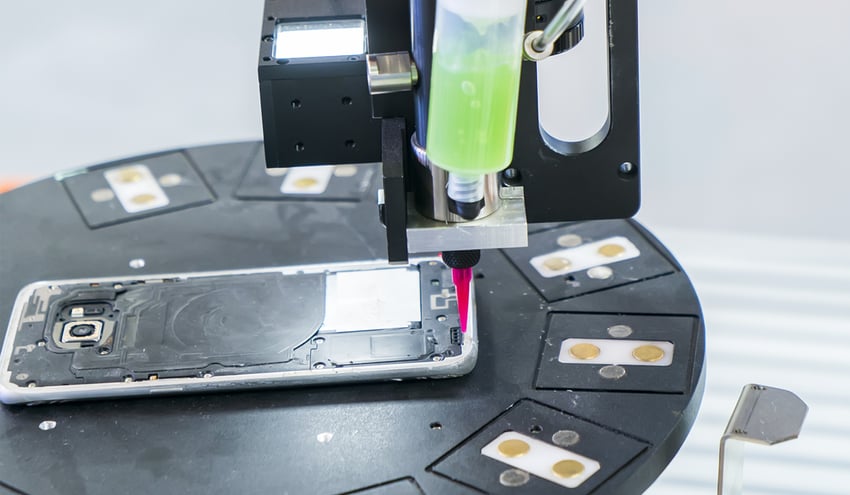

- The application of a liquid adhesive, adhesive tape, coating, paint, or other substance

- The steps involved in adding primers

- Manual cleaning steps like hand-wiping

Unintentional changes may include:

- The presence of aerosols or silicone in a specific area of the facility can lead to environmental contamination caused by the part or material being exposed to them.

- Materials or parts are not being handled and shipped with the necessary care and in a controlled manner.

- Unknown formula changes in solvents or materials imposed by the supplier that affect the adhesion operation.

- The additive blooming of chemical substances migrating to the surface of polymeric materials.

- Unintentional human choices

It is important to acknowledge that the changes taking place at each Critical Control Point can lead to either beneficial or detrimental outcomes.

Examples of Positive and Negative Changes on Material Surfaces

Positive Changes:

The surface that undergoes plasma treatment or corona activation exhibits an increased surface energy, making it suitable for high-quality bonds.

Negative:

A material surface has been overtreated using plasma or corona treatment, and even though it has gone through the treatment operation, the surface has actually been damaged and is not in a state that would allow for reliable adhesion.

Positive:

A component goes through a vapor degreasing process and is fully clean and ready for the joining process.

Negative:

A component goes through a vapor degreasing process that has not had the fluid changed at the proper time and actually applies contaminants to this component from parts that were previously sent through the same process.

Measuring the surface state before and after each other, these Critical Control Points give extremely valuable information to manufacturers about how they are affecting the quality of their surfaces.

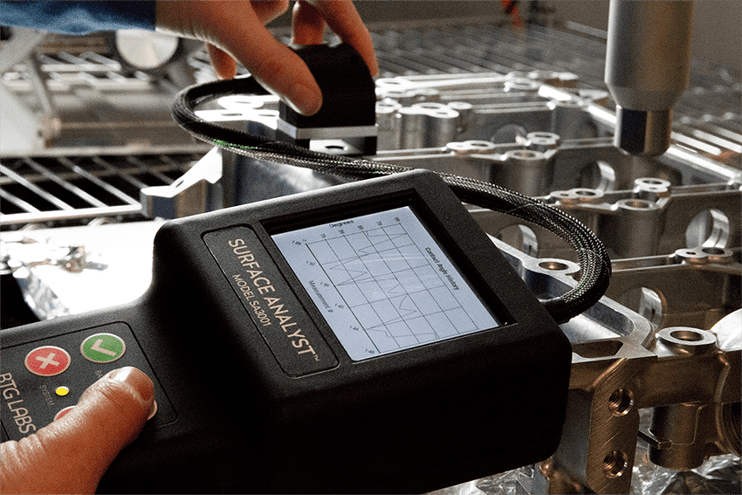

Own Your Process with Non-Destructive Surface Quality Evaluation

Manufacturers who look outside the usual places where adhesive bonding failures are investigated stand a much better chance of actually discovering the root cause and, ultimately, controlling their process to solve the problem. The best way to do this is to know where to look. Then, implement quantitative surface state inspections so direct action can be taken to bring it to the proper specification if it deviates from the prescribed standard.

To learn more about developing an effective and fulsome root cause analysis plan, download the eBook "The Future of Manufacturing: A Guide to Intelligent Adhesive Bonding Technologies & Methodologies."

.jpg?width=850&height=495&name=metal-brazing-copper-component%20(reduced).jpg)