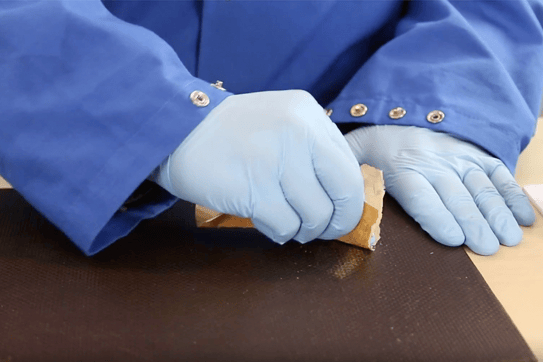

The Hidden Variable in Surface Prep: The Human Factor

KEY TAKEAWAYS Manual surface preparation introduces significant variability. Even with identical materials and written instructions, operator technique can dramatically change surface outcomes. Human execution impacts adhesion more than many realize. Subtle differences in pressure, angle,...

Read

Topics:

Posts by Topic

Precision Surface Measurement Redefined: Quality Use Cases for BConnect

KEY TAKEAWAYS How BCMobile enables fast, accurate, and repeatable surface energy measurement outside the lab.This article explains how BCMobile combines patented Ballistic Deposition, top-down imaging, and machine learning to deliver reliable water contact angle measurements in real-world...

Read

Topics:

3 Things You Need to Control for Proper Adhesion

The “What,” “Way,” and “The Surface” Behind Reliable Surface Bonding In manufacturing environments where bonding, coating, printing, or sealing takes place, success is never accidental. Whether you’re assembling automotive interiors, medical devices, electronics, or aerospace composites, adhesion...

Read

Topics:

Invisible Problems, Measurable Solutions: A New Approach to Mold Maintenance

At PolyCon 2025 in Milwaukee, Brighton Science unveiled a breakthrough approach to mold maintenance—one that makes invisible surface problems visible and measurable. The session, “Invisible Problems, Measurable Solutions,” was led by Kaitlin Carroll, Customer Success Manager at Brighton Science....

Read

Topics:

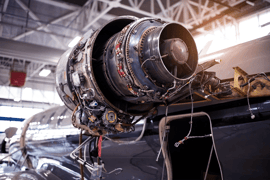

Surface Treatment of Thermoplastics for Aerospace Components

The Aerospace and Defense industry is booming. In 2024, global aerospace investments were nearly $1.2 trillion, with the United States accounting for nearly $450 billion in aircraft and space systems manufacturing. This rapid expansion is driven by technological advancements and rising demand for...

Read

Topics:

From Innovation to Standard: How Water Contact Angle Became the Surface Readiness Benchmark

A Common Language for an Uncommon Challenge One of the biggest barriers in global manufacturing is the lack of a shared language for surface quality. Engineering, operations, and suppliers often rely on guesswork or legacy tests.

Read

Topics:

Beyond Surface Prep: How Manufacturers Are Using Water Contact Angle to Control Adhesion Quality

Introduction Adhesion failures are among the most common yet preventable issues in composite bonding, coatings, and sealants. Whether in aerospace, automotive, or medical manufacturing, poor surface preparation can lead to structural weaknesses, warranty claims, and costly rework. But what if the...

Read

Topics:

Enhancing Automotive Manufacturing with Surface Intelligence

The Evolution of Automotive Materials and Their Challenges The automotive industry is constantly evolving, with manufacturers adopting advanced materials to improve strength, fuel efficiency, and durability while reducing weight and cost. Traditional materials like steel and iron are increasingly...

Read

Topics:

Maximizing Composite Adhesion with Water Contact Angle Analysis: Why Surface Preparation Matters

Composite materials are essential in industries like aerospace, automotive, and medical devices because they offer a combination of strength and lightweight properties. But no matter how advanced these materials are, their performance relies on proper surface preparation. If a surface isn’t...

Read

Topics:

The High Cost of Molding Defects: Protect Your Bottom Line

Imagine crafting a colossal mold, a behemoth capable of shaping fiberglass and composites into the intricate contours of a plane wing, the sleek hull of a boat, or even the entire body of a bus. It's a monumental task, requiring months of meticulous preparation and planning. As you gear up to start...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Guess the Contact Angle: IPA Wiped Composite Material

This 'Guess the Contact Angle' video is the first of our next series of videos focusing on how contact angle changes when a composite surface is cleaned or treated in various ways. The contact angle featured in this demo is formed by a water droplet deposited using the handheld Surface Analyst on...

Read

Topics:

Surface Preparation for Primer Coating of Composites in Aerospace Applications

Achieving a flawless, long-lasting paint job on an aircraft is a complex undertaking. This multi-stage process starts well before the final coat graces the wings and tail. Components are meticulously molded, prepared (often involving multiple steps), assembled, and then coated with primers and...

Read

Topics:

Topcoat to Primer Surface Reliability for Aircraft Painting

Adhesion problems don’t have a preference when it comes to the kind of damage they cause. Whether the end result is structural or cosmetic, adhesion-related failure headaches for manufacturers abound. One of the most crucial aesthetic operations for aircraft OEMs is the topcoat of paint, although...

Read

Topics:

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

Everything Breaks: What Reliability Means for Adhesively Bonded Products

The seemingly easy and obvious answer to the question implied in the title of this article is: reliability means no failures whatsoever forever and ever, amen. Sadly, it’s not quite so simple.

Read

Topics:

How to Bond Fiber Reinforced Plastics for Harsh Environments

Many manufacturers have a dual performance concern when their products are out there in the world being used in whatever capacity they were designed for. These parallel interests are: how to maintain the appearance and how to guarantee structural integrity through common usage of the products.

Read

Topics:

Study Proves the Surface Analyst is Dependable for Process Control

One of our favorite services we provide to manufacturers is to help optimize surface preparation techniques for their particular materials and products. It’s our specialty and one of our biggest passions. We feel so strongly about it because we know that if you, as a manufacturer, are able to...

Read

Topics:

Automotive Series: Surface Preparation of Composite Surfaces

Building a More Fuel-Efficient Automobile The pursuit of producing a more fuel-efficient automobile does not rely solely on the efficiency of the engine. A great amount of fuel efficiency gains are possible not because of improvements to engine design but because of improvements in materials....

Read

Topics:

.png?width=372&height=180&name=adhesion-failure%20(2).png)