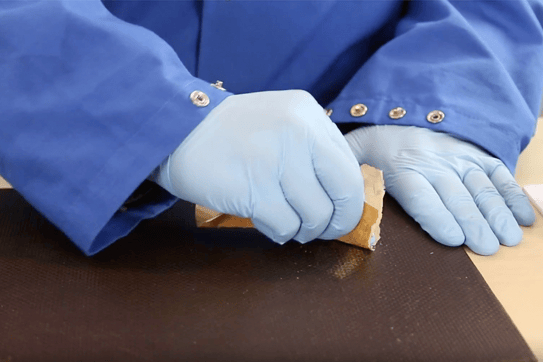

The Hidden Variable in Surface Prep: The Human Factor

KEY TAKEAWAYS Manual surface preparation introduces significant variability. Even with identical materials and written instructions, operator technique can dramatically change surface outcomes. Human execution impacts adhesion more than many realize. Subtle differences in pressure, angle,...

Read

Topics:

Posts by Topic

Precision Surface Measurement Redefined: Quality Use Cases for BConnect

KEY TAKEAWAYS How BCMobile enables fast, accurate, and repeatable surface energy measurement outside the lab.This article explains how BCMobile combines patented Ballistic Deposition, top-down imaging, and machine learning to deliver reliable water contact angle measurements in real-world...

Read

Topics:

How to Control Additive Blooming in Polymer Films

Key Takeaways Additive blooming is a common and often hidden cause of adhesion, sealing, and printing failures in polymer films. Certain additives are designed to migrate, but uncontrolled migration can undermine surface treatments. Blooming is driven by molecular mobility, temperature,...

Read

Topics:

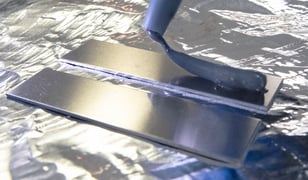

3 Things You Need to Control for Proper Adhesion

The “What,” “Way,” and “The Surface” Behind Reliable Surface Bonding In manufacturing environments where bonding, coating, printing, or sealing takes place, success is never accidental. Whether you’re assembling automotive interiors, medical devices, electronics, or aerospace composites, adhesion...

Read

Topics:

The Best Method of Controlling HMDS Use in Semiconductor Manufacturing

Key Takeaways Hexamethyldisilazane (HMDS) is essential for creating a hydrophobic wafer surface that enables strong photoresist adhesion during photolithography. The effectiveness of HMDS depends heavily on surface preparation, moisture removal, and controlled vapor deposition conditions. ...

Read

Topics:

Surface Treatment Methods: A Practical Guide for Manufacturers

Key Takeaways Effective surface treatment is essential for strong, predictable adhesion in bonding, coating, printing, and sealing processes. Each treatment method has distinct advantages, limitations, and material compatibility considerations. Monitoring chemical surface condition is as important...

Read

Topics:

Is Roughness as Important as Surface Cleanliness to Adhesion?

Key Takeaways Surface roughness alone does not determine adhesion performance. Many benefits attributed to roughening actually come from unintentional cleaning during surface prep. Adhesion depends primarily on the chemical condition of the top one to five molecular layers. Surface aging and...

Read

Topics:

How to Measure Surface Tension

Key Takeaways Surface tension describes the molecular forces that determine how liquids interact with solids and directly affects adhesion, coating, and wetting performance. Measuring surface tension provides predictive insight into product reliability and process control. Dynamic surface tension...

Read

Topics:

The Cost of Poor Quality in Manufacturing and How Brighton Science Helps Stop It Before It Starts

In today’s fast-paced manufacturing environment, quality issues are more than just operational setbacks; they’re financial liabilities. The Cost of Poor Quality (COPQ) refers to the total financial burden a company incurs due to substandard products, inefficient processes, or rework.At Brighton...

Read

Topics:

What is the Difference Between Surface Free Energy and Surface Energy?

Key Takeaways Surface free energy and surface energy are interchangeable terms in manufacturing contexts; both describe the energy available at a material’s surface to enable interactions such as bonding, coating, printing, and cleaning. Surface energy has two components, dispersive and polar....

Read

Topics:

What is the Difference Between Surface Tension and Surface Energy

Key Takeaways: Surface tension describes the attractive forces between molecules at the surface of a liquid, while surface energy describes the same phenomenon at the surface of a solid. Both are expressions of intermolecular attraction, which determines whether two materials will adhere...

Read

Topics:

Invisible Problems, Measurable Solutions: A New Approach to Mold Maintenance

At PolyCon 2025 in Milwaukee, Brighton Science unveiled a breakthrough approach to mold maintenance—one that makes invisible surface problems visible and measurable. The session, “Invisible Problems, Measurable Solutions,” was led by Kaitlin Carroll, Customer Success Manager at Brighton Science....

Read

Topics:

What are Surfactants and How Do They Impact Surface Tension?

Key Takeaways: Surfactants are chemical compounds that lower a liquid's surface tension, allowing it to spread and interact with solids more easily. They are essential ingredients in cleaners, coatings, adhesives, and inks, but residual surfactants left behind can contaminate surfaces and weaken...

Read

Topics:

The Water Break Test as a Surface Measurement Gauge

Key Takeways The water break test is a simple, traditional method for assessing surface cleanliness, but it is subjective and limited in precision. It only detects hydrophobic contaminants and cannot quantify surface energy or detect hydrophilic residues such as surfactants. Because results are...

Read

Topics:

Silicone Contamination: The Problem You Don’t Know You Have

Most engineers expect failures to trace back to obvious causes, a material defect, an operator mistake, or a process error. But sometimes the culprit is hiding in plain sight: silicone contamination.

Read

Topics:

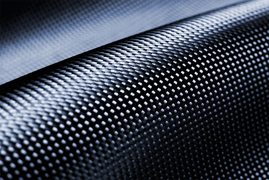

The Key to Stronger Composite Repairs? Measuring Surface Prep Before Bonding

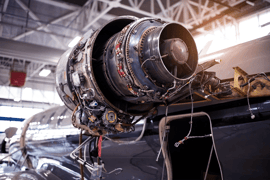

Bond Repair: Making Surface Prep Measurable Bonding composites is never simple, but repairing them is an entirely different challenge. Unlike pristine manufacturing environments where parts are prepped and assembled under controlled conditions, repairs often happen in less-than-ideal circumstances:...

Read

Topics:

Why Water Contact Angle Became the Benchmark for Surface Quality

From Research Labs to Factory Floors In manufacturing, it’s often assumed that adhesion problems stem from the adhesive itself. But the truth is, many failures originate at the surface. Even the best adhesives, paints, or coatings can fail to perform if a surface isn't adequately prepared. Despite...

Read

Topics:

How Surface Measurements Help Medical Device Makers Avoid Delays

Medical Devices Face Unique Regulatory Pressures — and Surface Quality Plays a Bigger Role Than You Think Product reliability isn't optional in the medical device industry; it’s a regulatory requirement. Manufacturers must meet a growing number of global quality standards, from FDA regulations to ...

Read

Topics:

How the Surface Intelligence Maturity Model Prevents Adhesion Failures and Reduces Manufacturing Costs

Executive Summary: Why You Need the Surface Intelligence Maturity Model Manufacturers across industries are losing millions to unseen surface issues that cause adhesion failures, recalls, and rework. Brighton Science’s new Surface Intelligence Maturity Model gives organizations a clear, five-stage...

Read

Topics:

From Innovation to Standard: How Water Contact Angle Became the Surface Readiness Benchmark

A Common Language for an Uncommon Challenge One of the biggest barriers in global manufacturing is the lack of a shared language for surface quality. Engineering, operations, and suppliers often rely on guesswork or legacy tests.

Read

Topics:

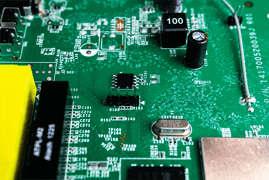

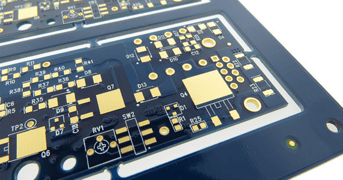

Ensuring Conformal Coating Reliability with Surface Intelligence

The Crucial Role of Conformal Coatings in Electronics Electronic components are the backbone of modern technology, from implantable medical devices and navigational equipment to sensor packages in cars and everyday cell phones. These delicate and exposed pieces are vulnerable to various...

Read

Topics:

Speed vs. Quality: How Manufacturing Sectors Balance Risk, Cost, and Innovation

In every manufacturing environment, there's one constant tension: how to move fast without breaking things. Whether you're building airplanes, cars, consumer electronics, or medical devices, the same tradeoff exists: production speed versus product quality.

Read

Topics:

Beyond Surface Prep: How Manufacturers Are Using Water Contact Angle to Control Adhesion Quality

Introduction Adhesion failures are among the most common yet preventable issues in composite bonding, coatings, and sealants. Whether in aerospace, automotive, or medical manufacturing, poor surface preparation can lead to structural weaknesses, warranty claims, and costly rework. But what if the...

Read

Topics:

Enhancing Automotive Manufacturing with Surface Intelligence

The Evolution of Automotive Materials and Their Challenges The automotive industry is constantly evolving, with manufacturers adopting advanced materials to improve strength, fuel efficiency, and durability while reducing weight and cost. Traditional materials like steel and iron are increasingly...

Read

Topics:

The Hidden Factor in Product Performance: Why the Top Few Molecular Levels of a Surface are Critical to Product Reliability

Manufactured and assembled products almost always require adhesion or cleaning steps—whether bonding, coating, painting, or printing—which makes the quality of those surfaces essential to the product's final performance. Contrary to conventional assumptions, surfaces are highly variable and...

Read

Topics:

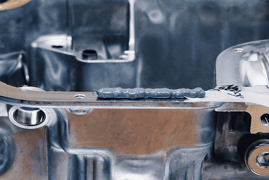

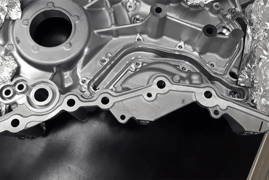

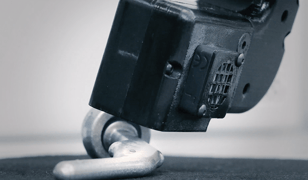

Ensuring Gasket Reliability: The Critical Role of Surface Quality in Formed-in-Place Gasket Applications

Formed-in-place gaskets (FIPG) have revolutionized sealing solutions across industries that require high-reliability seals. While there are many types of gaskets, a FIPG is created from a specific method where a liquid sealant, typically applied by an automated dispensing system, is dispensed...

Read

Topics:

What Automotive Manufacturers Need to Know About Surface Analysis for Polymer Bonding and Coating

Polymers have taken center stage in automotive manufacturing. Their light weight, durability, and versatility make them ideal for many applications ranging from dashboards and door panels to bumper facias and fenders. However, as any product development or quality control professional will tell...

Read

Topics:

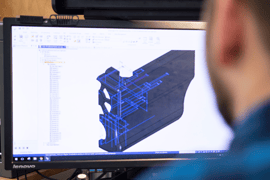

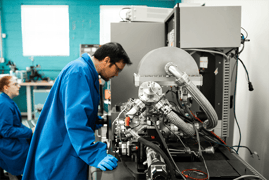

Comprehensive Guide to Understanding X-ray Photoelectron Spectroscopy (XPS) for Surface Analysis

X-ray photoelectron spectroscopy (XPS) is a sensitive surface analysis technique with broad applications across numerous industries. Beyond its fundamental role in materials characterization, XPS can provide critical information to solve real-world material challenges. With the help of Rose...

Read

Topics:

Environmental Silicone: Detection, Control, and Impact on Adhesion in Manufacturing

Silicone contamination is a huge problem in many painting and bonding applications. It’s impossible to see, hard to remove, and it creeps in unseen like a ghost. Where the harm it can cause is recognized, businesses go to great lengths to clean surfaces and exclude potential sources of...

Read

Topics:

The High Cost of Molding Defects: Protect Your Bottom Line

Imagine crafting a colossal mold, a behemoth capable of shaping fiberglass and composites into the intricate contours of a plane wing, the sleek hull of a boat, or even the entire body of a bus. It's a monumental task, requiring months of meticulous preparation and planning. As you gear up to start...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Top 5 Strategies for Manufacturing Plant Managers to Overcome Challenges

Leadership of a manufacturing plant demands exceptional skill. Plant managers navigate a dynamic landscape of ever-evolving responsibilities. Drawing on a decade of collaboration with hundreds of companies across countless operational challenges, we've identified key insights to help tackle these...

Read

Topics:

Surfaces Matter: Why Tracking Material Surface Quality is Critical for Aircraft Safety

The relentless pursuit of safety underpins every aspect of aerospace manufacturing. However, two significant hurdles impede this goal: verification and non-destructive testing. Destructive testing, the traditional method for assessing bond strength, is impractical for composite materials – the...

Read

Topics:

Unlock the Key to Successful Adhesive Bonding: What You Need to Know Beyond Adhesive Technical Data Sheets

Manufacturers are increasingly utilizing a greater number of adhesive materials as a joining technique in the construction of their products, and the importance of these uses is continuously increasing with each passing year. As a result, the consequences of adhesive bond failures are becoming more...

Read

Topics:

Contact Angle Goniometer 101: Guide to Measuring Contact Angle

Have you wondered why some paints or coatings adhere effortlessly while others leave blisters or bubbles? The answer lies in wettability, the intricate dance between a liquid and a surface governed by a powerful principle known as contact angle. And measuring this microscopic tango? That's where...

Read

Topics:

Fundamentals of Adhesion Science & Why 3 Molecular Layers Matter

Adhesion is crucial in microscopic and macroscopic worlds, yet it is an often-overlooked force. Adhesion acts as the invisible glue that unites objects, both massive and minute. Adhesion allows us to construct monumental structures like bridges, buildings, and airplanes. It enables us to glue wood...

Read

Topics:

The Thought Behind our New Brighton Academy

Over the past decade, we have been told that our science is the cornerstone of our customer relationships. Whether you’ve been with us from the beginning or just recently joined the BConnect community, during your journey with us, we’ve likely shared our scientific insights with you. This may have...

Read

Topics:

How Knowledge Sharing in Bonding Processes Drives Enterprise Success

Wind turbines have a problem: their giant blades fail more often than anticipated. Research on the issue, reported in the journal Materials, notes an average of 3,800 failures each year. Many of these result from adhesive bonding defects, which should be addressed and prevented through improved...

Read

Topics:

Adhesive Bonding vs. Mechanical Fastening in Product Design: The Pros and Cons

When creating their next innovative product, designers, and manufacturers strive to achieve optimal performance while minimizing assembly and materials costs. In this pursuit, they often focus on optimizing material usage. In the quest to achieve optimization, it is uncommon for excess materials to...

Read

Topics:

Unlock Success in Adhesive Bonding: The Definitive Troubleshooting Guide

Manufacturers have numerous options at their disposal when it comes to preventing product failures resulting from imperfect adhesive bonding. Often, the approach is to simply accept adhesive bonding failures as part of the scrap rate and move on. In other cases, companies may completely revamp...

Read

Topics:

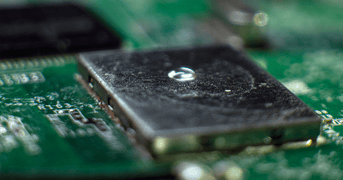

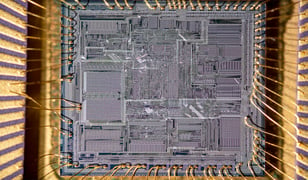

Ensuring Top-Quality Solder Joints on ENIG PCBs: Best Practices Unveiled

The field of printed circuit board (PCB) finishing and bonding methods has been growing and diversifying for decades. PCB design depends heavily on the use and environment of the electronic package, and those design decisions include what Surface Mount Technology (SMT) is employed. SMT involves the...

Read

Topics:

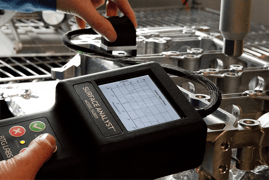

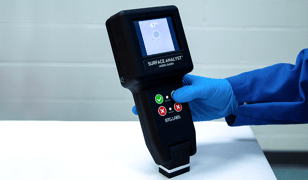

Surface Inspection 101: A Visual Guide to the Surface Analyst, Water Break Tests, and Dyne Ink

In the manufacturing industry, it is crucial to meet certain surface preparation requirements in order to ensure the safety and reliability of products. Various tests have been developed to determine if these requirements are being met and if the cleaning process has been effective enough to...

Read

Topics:

Contact Angle Analysis: Sealing Surface of Aluminum Castings

Surface Quality Requirements of Aluminum Castings Manufacturers widely utilize aluminum castings as the most successful way to create aluminum parts. However, this process can involve inorganic contaminants on the surface, which interfere with potential bonding, sealing, or coating. Scientists at...

Read

Topics:

Demystifying Dyne Levels: Understanding and Measuring Surface Quality

The evaluation of material surfaces in terms of quality has long relied on dyne testing. Despite their drawbacks, such as subjectivity, imprecision, damage to surfaces, and safety risks for users, dyne tests have remained popular among manufacturers due to their wide availability and affordability....

Read

Topics:

Non-Destructive Alternative to Dyne Testing for Reliable Quality Control

Dyne solutions have been the most common method of quality-checking material surface cleanliness for decades. Their ubiquity and low cost have led them to be heavily relied upon by manufacturers even though they are imprecise, destructive to surfaces, and harmful to the user. The science behind...

Read

Topics:

Identifying Adhesive Bond Failure Points in Manufacturing

One particular area that has proven to be a challenge in manufacturing is adhesion and surface quality. Research and development teams, product developers, and manufacturing operations frequently encounter difficulties with adhesion processes, such as coating or adhesion problems throughout the...

Read

Topics:

Surface Energy Measurement is the Key to Process Control and High Performance

When manufacturing companies take adhesion seriously, they can significantly improve their ability to achieve their business goals. The key is to take a strategic look at adhesion processes early in product development.

Read

Topics:

Why You Should Use Predictive Data in Building Material Manufacturing

The building industry relies heavily on adhesives and coatings to ensure structures are weatherproof, durable, and aesthetically pleasing. From modern flooring to sturdy roofs, these building materials rely on a strong bond – both literally and figuratively. However, unlike many other industries,...

Read

Topics:

Guaranteeing Anti-fog Coating Application on Automotive Headlights

The competitive nature of the automotive industry requires manufacturers to engineer the ideal product; failures, no matter how small, are unacceptable and can bring heavy consequences.

Read

Topics:

How to Fix Common Causes of Adhesion Problems

Manufacturers often have a large blind spot regarding the causes of adhesion problems. This blind spot makes it impossible to solve these problems and generates frustration and loss rather than productivity and adhesion success. Taking the blinders off and taking on adhesion failure at its...

Read

Topics:

Why a Surface Chemistry Input Should be Included in New Product Specifications

When development teams are looking to build a new product that includes a coating, bonding, painting, or sealing process, it's only natural to consider what kind of adhesive, coating, or paint will perform the best. While these selections are critical to the end product's success, development teams...

Read

Topics:

Importance of Adhesion & Composites in Lightweighting Cars

One of the most pressing questions on the minds of manufacturing engineers is how to take a load off. Lightweighting, or shedding pounds on assembled vehicles and machinery, is a critical puzzle in aerospace, marine, and, most acutely, automotive industries. In fact, with the pressure to optimize...

Read

Topics:

What are the Primary Causes of Chronic Adhesion Failures?

Adhesion problems tend to appear in the manufacturing process and then overstay their welcome. The chronic nature of so many adhesion issues is due to factors that many manufacturing companies are oblivious to. That’s not to fault the manufacturers. Until recently, there hasn’t been a reliable way...

Read

Topics:

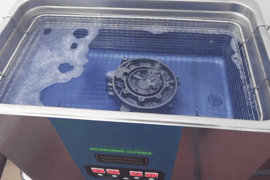

The Best Way to Qualify a Wash Method for Your Manufacturing Process

Parts washers are heavy-duty, hardworking machines that have become irreplaceable staples in automotive andmachined part manufacturing processes. As manufacturing processes have become more sophisticated, the industries using parts washers have expanded to includenot only industrial metals and...

Read

Topics:

Easy Ways to Find Manufacturing Adhesion Failure Sources

When adhesion failure plagues a manufacturing process, it can be particularly disruptive. A production process may be humming along just fine, and then it suddenly becomes clear that a coating is uneven, or paint is chipping (when it wasn’t before), joints are weaker than they had been, or film is...

Read

Topics:

How to Measure Contact Angle on Convex and Concave Surfaces

Historically, accurately measuring contact angles on concave and convex surfaces has been a challenge. The typical method used to measure contact angle on these types of surfaces has been with abenchtop goniometer. The challenges arise from how goniometers measurecontact angle—from a horizontal...

Read

Topics:

Why Automotive Glass Bonding Recalls Should be a Thing of the Past

Automotive glass is a technological marvel. Despite its clarity, much of how it's manufactured is unseen by the average driver. Silica compounds, tempering, and lamination all combine to create one of the most critical components of today’s motor vehicles. Unfortunately, though, things periodically...

Read

Topics:

The Surface Analyst™ Instantly Measures Contact Angle to Determine the Potential Adhesive Strength of Bonds

A Handheld Solution for Verifying Surface Cleanliness The Surface Analyst™ is an innovative handheld solution for use in the lab and on the factory floor. It reduces waste, rework, and recalls when poorly prepared substrate surfaces lead to bonding, coating, sealing, painting, or printing failure.

Read

Topics:

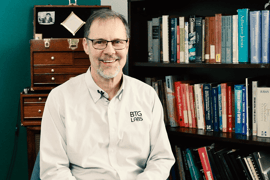

Meet Brighton Science's Chief Scientist, Giles Dillingham

A Deep History in Materials Science Founder and Chief Scientist of Brighton Science, Dr. Giles Dillingham's fascination with the connections between the invisible (the molecular structure of the world around us) and the perceivable (the properties and behavior of materials and objects) stems from a...

Read

Topics:

Contact Angle Measurements Guide Better, Data-Driven Quality Decisions

Deciding whether to reject a part or not based on a quality measurement always carries with it a finite risk: you could unknowingly decide that a perfectly good part is actually bad (a Type 1 error), or you might incorrectly conclude that a bad part is actually good (a Type 2 error). There is a...

Read

Topics:

How to Master Industrial Adhesion with Scientific Predictability

Manufacturers who produce products with surfaces that require paints, adhesives, or sealants face a challenge in determining the quality and reliability of the final product. The problem is often caused by the fact that most manufacturers don’t have complete control over three critical elements of...

Read

Topics:

Why Knowing Water Contact Angle is Important for Successful Adhesive Performance

Adhesives are an integral part of modern manufacturing, but choosing the right adhesive is only one part of the equation. It’s well known that you won’t get a reliable bond with an adhesive if you just slap the adhesive onto your material without doing anything to prepare that surface. What ISN’T...

Read

Topics:

How to Prevent Coating Failure and Corrosion in Polymeric Materials

These days, if you see a painted product, it is likely a polymer-based coating providing a striking and powerful barrier between the underlying material and elements in the atmosphere that want to corrode that material. Polymer coating technology has advanced tremendously in the last decade....

Read

Topics:

How Shoe Manufacturers Maintain Adhesion Quality Through Material Changes

There are many reasons why sneakerheads love the shoes they covet. Athletic shoes have become one of the most sought-after clothing items due to their aesthetic appeal and shoe manufacturers' ever-evolving material innovations.

Read

Topics:

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

Manufacturing Best Practices for Business Continuity Plans

The manufacturing industry has undergone unprecedented challenges in recent years, necessitating a fundamental re-evaluation of business continuity strategies. While economic downturns have historically presented obstacles, the complexities of today’s globalized and interconnected business...

Read

Topics:

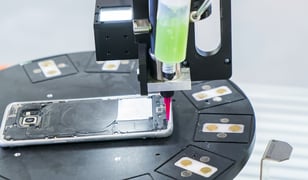

Better Consumer Electronics Reliability: Coatings and Adhesives

In a recent study conducted by Instrumental, the top ten most common manufacturing defects were examined. The number one defect that manufacturers fight against is a deficiency in glue.

Read

Topics:

Reliable Wire Bonding Through Quality Data Collection for Industry 4.0

Wire bonding and sintering are critical processes involved in the manufacture of a majority of electronic devices. These processes are used to connect silicon chips, integrated circuits (ICs), and electrical components to their housings and boards.

Read

Topics:

Everything Breaks: What Reliability Means for Adhesively Bonded Products

The seemingly easy and obvious answer to the question implied in the title of this article is: reliability means no failures whatsoever forever and ever, amen. Sadly, it’s not quite so simple.

Read

Topics:

Process Control Innovations for Card Manufacturers

We've all been there: the frustrating moment at checkout when your card decides to play dead, leaving you scrambling for another way to pay for that mountain of nachos. For credit and debit card manufacturers, these glitches are the ultimate nightmare.Sure, factors like rewards programs and bank...

Read

Topics:

Using Data to Improve Ink Adhesion to Polymer Film

One of the most frustrating aspects of experiencing a problem in manufacturing isn't necessarily the issue itself, but rather, it's the difficulty of accurately determining and communicating what the problem actually is.

Read

Topics:

How to Get a Stronger Weld Through Cleaning

Even though we look around us and see plastic everywhere, in every shape and imaginable application, metals are still a more commonly used raw material in machined products. Metals are the legacy material of choice due to their strength and relative ease of bonding. However, advances in polymers...

Read

Topics:

How to Control Surface Quality for Bonding Dissimilar Materials

We’ve mentioned many times in various articles that bonded material systems are becoming the norm for manufacturers in nearly every industry. In order to make finished products more efficient in terms of weight, cut material costs, accommodate more automated processes, lessen the need for repairs...

Read

Topics:

How to Bond Fiber Reinforced Plastics for Harsh Environments

Many manufacturers have a dual performance concern when their products are out there in the world being used in whatever capacity they were designed for. These parallel interests are: how to maintain the appearance and how to guarantee structural integrity through common usage of the products.

Read

Topics:

Coatings on Car Sensors and Why We Don’t Have Driverless Cars Yet

Our relationship with our vehicles may have changed in the past few months, with the idea of commuting to work looking more like a shuffle to the desk across the room rather than a drive to the office across town. However, cars have not dropped in prominence in our society. With health risks now...

Read

Topics:

Controlling Parts Washing Methods for Medical Components

Cleanliness is next to production standardization requirements for medical device manufacturers (as the old saying goes). Devices built to be inserted within the human body understandably need to meet the highest cleanliness standards. Companies in this industry have already known what many of us...

Read

Topics:

Single vs Multi-fluid Contact Angle Techniques Part 1: Surface energy and the attractions between substances

This is part one of a two-part series explaining the finer points of Brighton Science's approach to helping companies build reliability into their cleaning and adhesion processes through consultation and implementation of novel inspection equipment. These two articles are based on this technical...

Read

Topics:

Proposed ASTM Standard Will Ease the Pain of Manufacturers

An exciting development is taking place to make surface quality and cleanliness inspection technology more available to all manufacturers. We have collaborated with ASTM International and other stakeholders to craft a revision to establish a standard use of handheld goniometers in production...

Read

Topics:

Demystifying the Greatest Metal Brazing Process Challenges

When thinking about what manufacturing looks like, most people envision sparks flying, metal clanking, and fires blazing. This isn’t too far off the mark since metals were used to bond joints together to build larger, sturdier, and more stable structures before the first Industrial Revolution,...

Read

Topics:

How to Protect Overmolded Connectors for Medical Devices

Protective coverings are part and parcel of our lives these days. For industries reliant upon electronic components and connectors, protective coverings in the form of polymeric over-molding encapsulation need to remain sealed and impervious to the environment.

Read

Topics:

Cleaning Strategies for Great Adhesion

Cleanliness in manufacturing gains avid devotees all the time. Once the importance of cleanliness is grasped, it’s nearly impossible to think about manufacturing processes without considering the pervasive impact cleanliness has on every aspect and feature of the process.

Read

Topics:

The Tools & Skills to Address Adhesion Problems in Production

When adhesion issues become apparent in a manufacturing process, they can seem to come out of nowhere. When coatings on circuit boards delaminate and cause shorts, when automotive glass doesn’t properly seal and moisture is let through, or when implantable medical devices aren’t meeting cleanliness...

Read

Topics:

The 3 Crucial Elements for High-Performance Adhesion in Manufacturing

Excellent adhesion relies on the manufacturer’s ability to understand and control three distinct yet interrelated elements. In manufacturing, adhesive bonding takes many forms, but the fundamental principles of adhesion are always the same. Even if the application is metal joint welding, Parylene...

Read

Topics:

Best-practice Surface Preparation Processes for New Products

New Product Development is an essential component to the successful growth of companies that always challenge themselves to improve and innovate. Getting this design stage right is pivotal in that it sets in motion everything the product will be and how well it will perform.

Read

Topics:

How to Minimize Production Scrap from Adhesion Failures

In manufacturing, it is extremely difficult to eliminate all inefficiencies and production deficits. It is not uncommon for setbacks to occur in the form of scrap and rework due to product failure before the product is shipped to the market or recalls and returns after the product has already been...

Read

Topics:

How to Ensure a Manufacturing Surface is Clean Enough for Adhesion

Cleanliness and adhesion go hand-in-hand. If you’re looking for an adhesion process to be successful, you are also absolutely interested in cleaning the materials involved in the application. To get the most out of your cleaning operations, it’s imperative to know three things: What does clean...

Read

Topics:

How Surface Quality Devices Can Validate Adhesion Specs

Regulatory specifications in manufacturing exist to ensure that the highest quality, safest, and most useful products are created. These are devised internally through research and development testing to meet customer demands and through external regulatory bodies to protect consumers and public...

Read

Topics:

Can a Surface Science Lab Ensure Adhesion in Manufacturing?

Manufacturers utilize research and design laboratories all the time. To scale new products up to the production line, years of toiling in testing labs are done to ensure that everything goes off without a hitch once production starts.

Read

Topics:

Why a Surface Quality Inspection Process Ensures Adhesion

Manufacturing processes that involve bonding, coating, sealing, printing, painting, laminating, or cleaning need a metric to measure the surface quality of the materials involved. Without such a metric, it is impossible to predict whether the adhesion process will be successful or if it's on the...

Read

Topics:

7 Most Valuable Tips to Ensure Proper Adhesion in Production

Adhesion problems are an insidious concern to manufacturers in any industry with printing, painting, bonding, laminating, or coating applications. These problems settle into a production process, and they manifest in many different ways. An adhesion issue could look like a joint failure, uneven...

Read

Topics:

Tales from Brighton Science's Materials & Processing Lab

In the Brighton Science Materials and Processing Laboratory, magic happens. Or, at least, it seems that way. In the lab, our specialists see the unseen. They use expertise, specialized tools, and data to reveal the invisible.

Read

Topics:

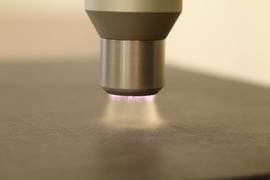

Surface Treatment Processes: Flame Treatment

Flame treatment is a surface activation treatment process used to chemically modify a surface for better adhesion. This process is typically used on low-energy surfaces that can be difficult to adhere to, such as plastics and composites. The treatment is also very gentle, posing low risk to the...

Read

Topics:

Inside Brighton Science's Lab: Advanced Materials and Process Experts

Brighton Science Lab Capabilities The history of Brighton Science (formerly BTG Labs) is rooted in adhesion research. Originally a development lab, Brighton Science specialized in plasma polymerized coatings. The engineers worked with coatings containing corrosion-resistant and anti-microbial...

Read

Topics:

Automotive Series: Surface Preparation of Composite Surfaces

Building a More Fuel-Efficient Automobile The pursuit of producing a more fuel-efficient automobile does not rely solely on the efficiency of the engine. A great amount of fuel efficiency gains are possible not because of improvements to engine design but because of improvements in materials....

Read

Topics:

Ensuring Success for Automotive Formed-In-Place Gasket (FIPG) Sealing

Controlling Surface Condition in FIPG Application Increasingly, FIPG processes are replacing traditional gaskets for a variety of automotive applications, such as air filters, oil filters, door panels, and external engine parts. The advantages include cheaper material cost, higher throughput...

Read

Topics:

.png?width=372&height=180&name=adhesion-failure%20(2).png)

.png?width=372&height=180&name=Cleaning%20Processes%20(Blog).png)

![Identifying Adhesive Bond Failure Points in Manufacturing [Key Considerations]](https://www.brighton-science.com/hs-fs/hubfs/images/blog-images/instron-adhesion-test-blog.jpg?width=372&height=180&name=instron-adhesion-test-blog.jpg)

.jpg?width=372&height=180&name=metal-brazing-copper-component%20(reduced).jpg)