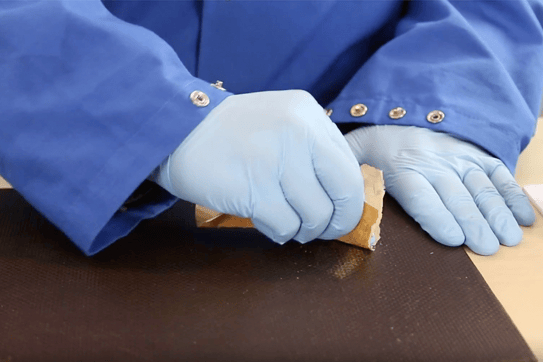

The Hidden Variable in Surface Prep: The Human Factor

KEY TAKEAWAYS Manual surface preparation introduces significant variability. Even with identical materials and written instructions, operator technique can dramatically change surface outcomes. Human execution impacts adhesion more than many realize. Subtle differences in pressure, angle,...

Read

Topics:

Posts by Topic

Precision Surface Measurement Redefined: Quality Use Cases for BConnect

KEY TAKEAWAYS How BCMobile enables fast, accurate, and repeatable surface energy measurement outside the lab.This article explains how BCMobile combines patented Ballistic Deposition, top-down imaging, and machine learning to deliver reliable water contact angle measurements in real-world...

Read

Topics:

3 Things You Need to Control for Proper Adhesion

The “What,” “Way,” and “The Surface” Behind Reliable Surface Bonding In manufacturing environments where bonding, coating, printing, or sealing takes place, success is never accidental. Whether you’re assembling automotive interiors, medical devices, electronics, or aerospace composites, adhesion...

Read

Topics:

Invisible Problems, Measurable Solutions: A New Approach to Mold Maintenance

At PolyCon 2025 in Milwaukee, Brighton Science unveiled a breakthrough approach to mold maintenance—one that makes invisible surface problems visible and measurable. The session, “Invisible Problems, Measurable Solutions,” was led by Kaitlin Carroll, Customer Success Manager at Brighton Science....

Read

Topics:

The Key to Stronger Composite Repairs? Measuring Surface Prep Before Bonding

Bond Repair: Making Surface Prep Measurable Bonding composites is never simple, but repairing them is an entirely different challenge. Unlike pristine manufacturing environments where parts are prepped and assembled under controlled conditions, repairs often happen in less-than-ideal circumstances:...

Read

Topics:

Why Water Contact Angle Became the Benchmark for Surface Quality

From Research Labs to Factory Floors In manufacturing, it’s often assumed that adhesion problems stem from the adhesive itself. But the truth is, many failures originate at the surface. Even the best adhesives, paints, or coatings can fail to perform if a surface isn't adequately prepared. Despite...

Read

Topics:

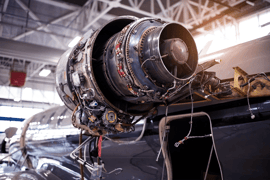

Surface Treatment of Thermoplastics for Aerospace Components

The Aerospace and Defense industry is booming. In 2024, global aerospace investments were nearly $1.2 trillion, with the United States accounting for nearly $450 billion in aircraft and space systems manufacturing. This rapid expansion is driven by technological advancements and rising demand for...

Read

Topics:

From Innovation to Standard: How Water Contact Angle Became the Surface Readiness Benchmark

A Common Language for an Uncommon Challenge One of the biggest barriers in global manufacturing is the lack of a shared language for surface quality. Engineering, operations, and suppliers often rely on guesswork or legacy tests.

Read

Topics:

How to Validate the Cleanliness of Optics (and Why It Matters More Than You Think)

In the world of optics, even a tiny speck of contamination can ruin a product. Whether you’re in precision manufacturing, medical imaging, or aerospace components, surface cleanliness isn’t just a box to check—it’s the foundation of performance and reliability.

Read

Topics:

Speed vs. Quality: How Manufacturing Sectors Balance Risk, Cost, and Innovation

In every manufacturing environment, there's one constant tension: how to move fast without breaking things. Whether you're building airplanes, cars, consumer electronics, or medical devices, the same tradeoff exists: production speed versus product quality.

Read

Topics:

Beyond Surface Prep: How Manufacturers Are Using Water Contact Angle to Control Adhesion Quality

Introduction Adhesion failures are among the most common yet preventable issues in composite bonding, coatings, and sealants. Whether in aerospace, automotive, or medical manufacturing, poor surface preparation can lead to structural weaknesses, warranty claims, and costly rework. But what if the...

Read

Topics:

The High Cost of Molding Defects: Protect Your Bottom Line

Imagine crafting a colossal mold, a behemoth capable of shaping fiberglass and composites into the intricate contours of a plane wing, the sleek hull of a boat, or even the entire body of a bus. It's a monumental task, requiring months of meticulous preparation and planning. As you gear up to start...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Surfaces Matter: Why Tracking Material Surface Quality is Critical for Aircraft Safety

The relentless pursuit of safety underpins every aspect of aerospace manufacturing. However, two significant hurdles impede this goal: verification and non-destructive testing. Destructive testing, the traditional method for assessing bond strength, is impractical for composite materials – the...

Read

Topics:

Adhesive Bonding vs. Mechanical Fastening in Product Design: The Pros and Cons

When creating their next innovative product, designers, and manufacturers strive to achieve optimal performance while minimizing assembly and materials costs. In this pursuit, they often focus on optimizing material usage. In the quest to achieve optimization, it is uncommon for excess materials to...

Read

Topics:

Identifying Adhesive Bond Failure Points in Manufacturing

One particular area that has proven to be a challenge in manufacturing is adhesion and surface quality. Research and development teams, product developers, and manufacturing operations frequently encounter difficulties with adhesion processes, such as coating or adhesion problems throughout the...

Read

Topics:

The Solution to Costly Aircraft Paint Adhesion Failure

The importance of understanding surface quality and being able to measure it in an accurate, reliable, and demonstrable way is important for ensuring a high-quality finish and, ultimately, a high-quality product. Any manufacturer that is not able to do this increases their risk of producing...

Read

Topics:

Top Challenges Product Development Teams Experience When Bringing a Product Concept to Manufacturing

Modern product development is fraught with challenges due in large part to the sophistication and complexity of the various elements that go into a final product – everything from materials and surface geometries to coatings, bonding, and even staff skills and competencies. Pitfalls await even the...

Read

Topics:

Surface Preparation for Primer Coating of Composites in Aerospace Applications

Achieving a flawless, long-lasting paint job on an aircraft is a complex undertaking. This multi-stage process starts well before the final coat graces the wings and tail. Components are meticulously molded, prepared (often involving multiple steps), assembled, and then coated with primers and...

Read

Topics:

3 Things You Need to Know to Create Reliable Bonds With Laser Cleaning

Manufacturers are always looking to create stronger, more durable, reliable, and lightweight products in the automotive and aerospace sectors. In this pursuit, they’ve often upgraded and swapped out material systems for metal alloys with lower density, better temperature tolerance, and corrosion...

Read

Topics:

How to Prevent Coating Failure and Corrosion in Polymeric Materials

These days, if you see a painted product, it is likely a polymer-based coating providing a striking and powerful barrier between the underlying material and elements in the atmosphere that want to corrode that material. Polymer coating technology has advanced tremendously in the last decade....

Read

Topics:

Topcoat to Primer Surface Reliability for Aircraft Painting

Adhesion problems don’t have a preference when it comes to the kind of damage they cause. Whether the end result is structural or cosmetic, adhesion-related failure headaches for manufacturers abound. One of the most crucial aesthetic operations for aircraft OEMs is the topcoat of paint, although...

Read

Topics:

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

Reliable and Efficient Manufacturing: Strategies You Can Use Now

Today, manufacturing requires a paradigm shift from reactionary whack-a-mole problem correction to taking a holistic approach. The mutually reliant elements of manufacturing are interwoven in both obvious and invisible ways. From supply chain communication to equipment dependability and from ...

Read

Topics:

How to Get a Stronger Weld Through Cleaning

Even though we look around us and see plastic everywhere, in every shape and imaginable application, metals are still a more commonly used raw material in machined products. Metals are the legacy material of choice due to their strength and relative ease of bonding. However, advances in polymers...

Read

Topics:

Demystifying the Greatest Metal Brazing Process Challenges

When thinking about what manufacturing looks like, most people envision sparks flying, metal clanking, and fires blazing. This isn’t too far off the mark since metals were used to bond joints together to build larger, sturdier, and more stable structures before the first Industrial Revolution,...

Read

Topics:

Inside Brighton Science's Lab: Advanced Materials and Process Experts

Brighton Science Lab Capabilities The history of Brighton Science (formerly BTG Labs) is rooted in adhesion research. Originally a development lab, Brighton Science specialized in plasma polymerized coatings. The engineers worked with coatings containing corrosion-resistant and anti-microbial...

Read

Topics:

.png?width=372&height=180&name=adhesion-failure%20(2).png)

![Identifying Adhesive Bond Failure Points in Manufacturing [Key Considerations]](https://www.brighton-science.com/hs-fs/hubfs/images/blog-images/instron-adhesion-test-blog.jpg?width=372&height=180&name=instron-adhesion-test-blog.jpg)

.jpg?width=372&height=180&name=metal-brazing-copper-component%20(reduced).jpg)