The Hidden Variable in Surface Prep: The Human Factor

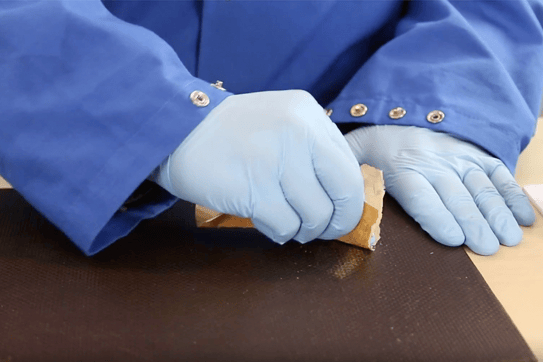

KEY TAKEAWAYS Manual surface preparation introduces significant variability. Even with identical materials and written instructions, operator technique can dramatically change surface outcomes. Human execution impacts adhesion more than many realize. Subtle differences in pressure, angle,...

Read

Topics:

Posts by Topic

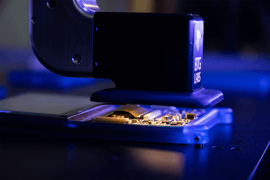

Precision Surface Measurement Redefined: Quality Use Cases for BConnect

KEY TAKEAWAYS How BCMobile enables fast, accurate, and repeatable surface energy measurement outside the lab.This article explains how BCMobile combines patented Ballistic Deposition, top-down imaging, and machine learning to deliver reliable water contact angle measurements in real-world...

Read

Topics:

How to Control Additive Blooming in Polymer Films

Key Takeaways Additive blooming is a common and often hidden cause of adhesion, sealing, and printing failures in polymer films. Certain additives are designed to migrate, but uncontrolled migration can undermine surface treatments. Blooming is driven by molecular mobility, temperature,...

Read

Topics:

3 Things You Need to Control for Proper Adhesion

The “What,” “Way,” and “The Surface” Behind Reliable Surface Bonding In manufacturing environments where bonding, coating, printing, or sealing takes place, success is never accidental. Whether you’re assembling automotive interiors, medical devices, electronics, or aerospace composites, adhesion...

Read

Topics:

What are Surfactants and How Do They Impact Surface Tension?

Key Takeaways: Surfactants are chemical compounds that lower a liquid's surface tension, allowing it to spread and interact with solids more easily. They are essential ingredients in cleaners, coatings, adhesives, and inks, but residual surfactants left behind can contaminate surfaces and weaken...

Read

Topics:

How the Surface Intelligence Maturity Model Prevents Adhesion Failures and Reduces Manufacturing Costs

Executive Summary: Why You Need the Surface Intelligence Maturity Model Manufacturers across industries are losing millions to unseen surface issues that cause adhesion failures, recalls, and rework. Brighton Science’s new Surface Intelligence Maturity Model gives organizations a clear, five-stage...

Read

Topics:

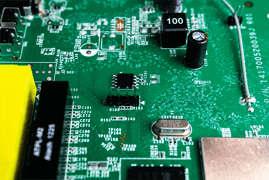

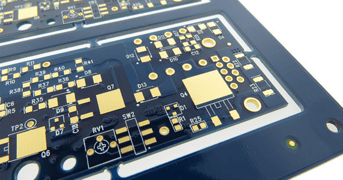

Ensuring Conformal Coating Reliability with Surface Intelligence

The Crucial Role of Conformal Coatings in Electronics Electronic components are the backbone of modern technology, from implantable medical devices and navigational equipment to sensor packages in cars and everyday cell phones. These delicate and exposed pieces are vulnerable to various...

Read

Topics:

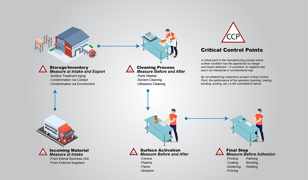

Managing Critical Control Points and Adhesion Failures with Next-Gen Technology

Bond failures remain a significant challenge for manufacturers, occurring on a large scale every week despite widespread awareness of the importance of surface readiness in bonding processes like sealing, coating, cleaning, and painting. Why? Because controlling adhesion throughout every...

Read

Topics:

The Hidden Factor in Product Performance: Why the Top Few Molecular Levels of a Surface are Critical to Product Reliability

Manufactured and assembled products almost always require adhesion or cleaning steps—whether bonding, coating, painting, or printing—which makes the quality of those surfaces essential to the product's final performance. Contrary to conventional assumptions, surfaces are highly variable and...

Read

Topics:

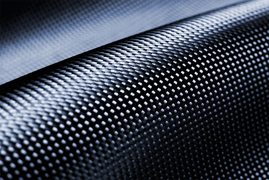

What Automotive Manufacturers Need to Know About Surface Analysis for Polymer Bonding and Coating

Polymers have taken center stage in automotive manufacturing. Their light weight, durability, and versatility make them ideal for many applications ranging from dashboards and door panels to bumper facias and fenders. However, as any product development or quality control professional will tell...

Read

Topics:

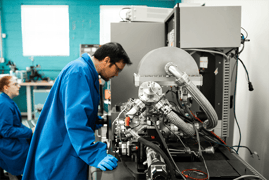

Comprehensive Guide to Understanding X-ray Photoelectron Spectroscopy (XPS) for Surface Analysis

X-ray photoelectron spectroscopy (XPS) is a sensitive surface analysis technique with broad applications across numerous industries. Beyond its fundamental role in materials characterization, XPS can provide critical information to solve real-world material challenges. With the help of Rose...

Read

Topics:

Top 5 Strategies for Manufacturing Plant Managers to Overcome Challenges

Leadership of a manufacturing plant demands exceptional skill. Plant managers navigate a dynamic landscape of ever-evolving responsibilities. Drawing on a decade of collaboration with hundreds of companies across countless operational challenges, we've identified key insights to help tackle these...

Read

Topics:

Navigating the Solvent Switch: A Sustainable Future for Parts Cleaning

Manufacturers who use solvent-based industrial parts cleaning processes must find alternative methods. Solvent-based cleaning processes use chemicals that emit or release Volatile Organic Compounds (VOCs). These are coming under increased scrutiny due to their harmful effects on health and the...

Read

Topics:

Corona Treatment Concerns You Need to Take a Closer Look At

Disclaimer: This article is NOT about COVID-19; it is about a surface treatment process for better surface preparation and adhesion properties in manufacturing. If you're looking for information about cleaning, here's an article that discusses the difference between biological cleanliness and...

Read

Topics:

Revolutionizing Multi-Site Manufacturing: Unleashing Operational Excellence Through Standardized Surface Quality Measurement

Are inconsistencies in bonding between your multi-site manufacturing lines creating poor-quality parts, like a band singing out of tune? This article will help you to identify and resolve those issues for good. Discover what causes inconsistent bonding, learn how to manage it, and get your...

Read

Topics:

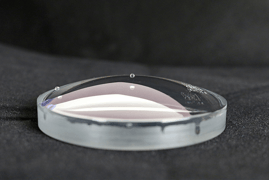

Contact Angle Goniometer 101: Guide to Measuring Contact Angle

Have you wondered why some paints or coatings adhere effortlessly while others leave blisters or bubbles? The answer lies in wettability, the intricate dance between a liquid and a surface governed by a powerful principle known as contact angle. And measuring this microscopic tango? That's where...

Read

Topics:

Fundamentals of Adhesion Science & Why 3 Molecular Layers Matter

Adhesion is crucial in microscopic and macroscopic worlds, yet it is an often-overlooked force. Adhesion acts as the invisible glue that unites objects, both massive and minute. Adhesion allows us to construct monumental structures like bridges, buildings, and airplanes. It enables us to glue wood...

Read

Topics:

How to Control Your Adhesive Process: Find the Critical Control Points

In today's highly competitive manufacturing environment, controlling the adhesive process is vital to ensuring product quality, consistency, and efficiency. Understanding the Critical Control Points (CCPs) within the adhesive process is essential for maintaining control and achieving desired...

Read

Topics:

On the Surface: An Overview of Surface Types and Measurement Challenges in Manufacturing

Of all the challenges manufacturers face, creating and optimizing critical surface processes for various materials can be very difficult. Traits such as location, size, shape, and texture can add to the challenge. The success of any critical surface process requires an in-line, fast, easy, and...

Read

Topics:

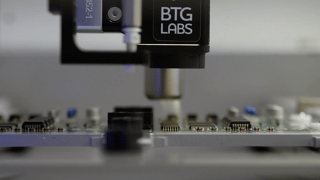

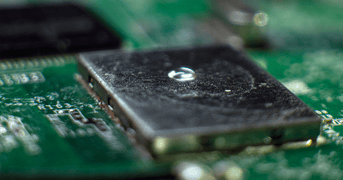

Ensuring Top-Quality Solder Joints on ENIG PCBs: Best Practices Unveiled

The field of printed circuit board (PCB) finishing and bonding methods has been growing and diversifying for decades. PCB design depends heavily on the use and environment of the electronic package, and those design decisions include what Surface Mount Technology (SMT) is employed. SMT involves the...

Read

Topics:

Surface Inspection 101: A Visual Guide to the Surface Analyst, Water Break Tests, and Dyne Ink

In the manufacturing industry, it is crucial to meet certain surface preparation requirements in order to ensure the safety and reliability of products. Various tests have been developed to determine if these requirements are being met and if the cleaning process has been effective enough to...

Read

Topics:

Demystifying Dyne Levels: Understanding and Measuring Surface Quality

The evaluation of material surfaces in terms of quality has long relied on dyne testing. Despite their drawbacks, such as subjectivity, imprecision, damage to surfaces, and safety risks for users, dyne tests have remained popular among manufacturers due to their wide availability and affordability....

Read

Topics:

Non-Destructive Alternative to Dyne Testing for Reliable Quality Control

Dyne solutions have been the most common method of quality-checking material surface cleanliness for decades. Their ubiquity and low cost have led them to be heavily relied upon by manufacturers even though they are imprecise, destructive to surfaces, and harmful to the user. The science behind...

Read

Topics:

Surface Energy Measurement is the Key to Process Control and High Performance

When manufacturing companies take adhesion seriously, they can significantly improve their ability to achieve their business goals. The key is to take a strategic look at adhesion processes early in product development.

Read

Topics:

How a Cleanliness Specification Increases Quality Process Control in the Supply Chain

Undoubtedly, you’ve been working toward specific sustainability goals and specializing your skills to do one thing well instead of multiple things moderately well or even poorly. But if your goals align around sustainability, it’s crucial to understand who your suppliers are and how your final...

Read

Topics:

The Relationship Between Total Quality Management Systems and Sustainability

In the age of sustainability practices becoming more of the norm, there are a few ways in which your company can both abide by new regulatory standards concerning sustainable changes to the chemicals used and have a positive impact on your total quality management standards.

Read

Topics:

The Knowing Doing Gap: How to Avoid Widespread Adhesion Issues

At Brighton Science, we talk about surface intelligence and how it can be used to optimize manufacturing processes from the earliest stages. In response, organizations often say, “Great! That’s the key to solving, preventing, and controlling bonding issues, right? But do we have surface...

Read

Topics:

How Surface Intelligence Can Improve Your Return on Investment

“For every company, its competitiveness comes from its ability to assimilate knowledge and failure - which I tell my kids all the time - failure is an opportunity to learn and feedback is a gift. And if we take the 'quick fix' we take the learning off the table.” Andy Reeher, CEO, Brighton Science

Read

Topics:

Why a Surface Chemistry Input Should be Included in New Product Specifications

When development teams are looking to build a new product that includes a coating, bonding, painting, or sealing process, it's only natural to consider what kind of adhesive, coating, or paint will perform the best. While these selections are critical to the end product's success, development teams...

Read

Topics:

Importance of Adhesion & Composites in Lightweighting Cars

One of the most pressing questions on the minds of manufacturing engineers is how to take a load off. Lightweighting, or shedding pounds on assembled vehicles and machinery, is a critical puzzle in aerospace, marine, and, most acutely, automotive industries. In fact, with the pressure to optimize...

Read

Topics:

What are the Primary Causes of Chronic Adhesion Failures?

Adhesion problems tend to appear in the manufacturing process and then overstay their welcome. The chronic nature of so many adhesion issues is due to factors that many manufacturing companies are oblivious to. That’s not to fault the manufacturers. Until recently, there hasn’t been a reliable way...

Read

Topics:

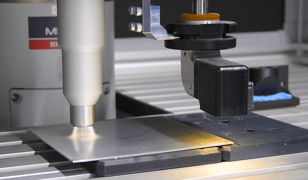

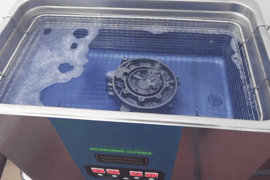

The Best Way to Qualify a Wash Method for Your Manufacturing Process

Parts washers are heavy-duty, hardworking machines that have become irreplaceable staples in automotive andmachined part manufacturing processes. As manufacturing processes have become more sophisticated, the industries using parts washers have expanded to includenot only industrial metals and...

Read

Topics:

4 Critical Questions for Assessing Product Development Risks

There are numerous obstacles to achieving and then maintaining a clean material surface. But there is one element that carries through the entire product lifecycle and can have a massive impact on the adhesion performance of the final product: TIME.

Read

Topics:

Why You Should Implement a Surface Cleanliness Specification Using Contact Angle

When cleaning invisible contaminants from a surface, you may ask yourself, "How do I know when the surface is clean, or how clean, is clean enough?" These are common questions that product development teams ask when developing new products that require surfaces to be thoroughly cleaned in order to...

Read

Topics:

How to Measure Contact Angle on Convex and Concave Surfaces

Historically, accurately measuring contact angles on concave and convex surfaces has been a challenge. The typical method used to measure contact angle on these types of surfaces has been with abenchtop goniometer. The challenges arise from how goniometers measurecontact angle—from a horizontal...

Read

Topics:

Guess the Contact Angle: Plasma Treated Aluminum

So far in our Guess the Contact Angle Series, we have brought you three videos demonstrating how contact angle changes depending on the state of the material surface: Contact angle measurement on a piece of aged, 'as is' aluminum Contact angle measurement on aluminum after cleaning it with an IPA...

Read

Topics:

What Is the Role of Surface Chemistry in Industry?

Manufacturing has become increasingly complex with the fusion of technologies that are blurring distinctions between the digital, physical, and biological worlds. Physical products and services have transformed significantly due to enhancements made possible by digital capabilities. New...

Read

Topics:

The Benefits of Benchmarking Surface Quality in Manufacturing

Certainty is the goal of every manufacturing process. Manufacturers must have total confidence that every aspect of their production process will go according to plan. The adhesion process needs to be controlled just like any other production operation, with accuracy and ongoing monitoring....

Read

Topics:

Does Your Organization Take A Holistic Approach to Innovation?

Innovation can be a scary thing. For companies built on order, predictability, and success, innovation can be unsettling. It can be messy, unpredictable, and prone to failure before producing a demonstrable payback. But innovation is vital. Without it, there can be no evolutionary growth or...

Read

Topics:

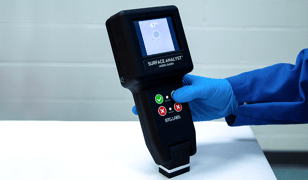

The Surface Analyst™ Instantly Measures Contact Angle to Determine the Potential Adhesive Strength of Bonds

A Handheld Solution for Verifying Surface Cleanliness The Surface Analyst™ is an innovative handheld solution for use in the lab and on the factory floor. It reduces waste, rework, and recalls when poorly prepared substrate surfaces lead to bonding, coating, sealing, painting, or printing failure.

Read

Topics:

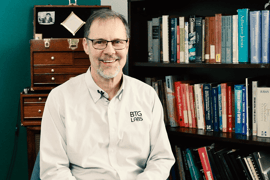

Meet Brighton Science's Chief Scientist, Giles Dillingham

A Deep History in Materials Science Founder and Chief Scientist of Brighton Science, Dr. Giles Dillingham's fascination with the connections between the invisible (the molecular structure of the world around us) and the perceivable (the properties and behavior of materials and objects) stems from a...

Read

Topics:

Why Manufacturers Can’t Achieve Manufacturing Innovation Gains by Simply Purchasing Equipment

Innovation is a word you hear tossed around frequently in various industries. Many organizations pursue innovation relentlessly as the key to their success and to gaining or maintaining a competitive edge. But innovation can be elusive for organizations that don’t quite know how to support it. As a...

Read

Topics:

Does Surface Roughness Impact Contact Angle Measurements?

When measuring and quantifying surface energy, a common question arises: "Does surface roughness impact contact angle measurements obtained by the Surface Analyst?" In response, Surface Intelligence experts at Brighton Science launched a research project to determine whether contact angle...

Read

Topics:

Top 5 Trends in Products & Manufacturing Today

Change is perhaps the one absolute constant in manufacturing. Developments - in materials, processes, machinery, testing, products, markets, and thousands of other things affecting manufacturing companies - happen daily.

Read

Topics:

Using Plasma for Surface Cleaning and Activation

This blog post is the first of a two-part series focusing on plasma. With the help of Rose Roberts, Ph.D., Senior Custom Applications and Materials Engineer, we will review plasma basics and discuss how plasma can be used for both cleaning and surface activation. We will also touch upon the...

Read

Topics:

3 Things You Need to Know to Create Reliable Bonds With Laser Cleaning

Manufacturers are always looking to create stronger, more durable, reliable, and lightweight products in the automotive and aerospace sectors. In this pursuit, they’ve often upgraded and swapped out material systems for metal alloys with lower density, better temperature tolerance, and corrosion...

Read

Topics:

Quantifying the Effectiveness of High Volume Metal Cleaning in Fresh and Aged Baths

In today’s video, we will show you how to quantify the surface quality of metals when using fresh and aged baths. We will demonstrate how Water Contact Angle (WCA) measurements can provide feedback in less than two seconds on the effectiveness of your cleaning process and will enable you to improve...

Read

Topics:

What to do When Your Contact Angle is out of Spec

Adhesive bonding can be used to create strong, reliable assemblies that perform extraordinarily well in the field. It is a deceptively sophisticated process frequently used in complex manufacturing environments. It is imperative to take a holistic view of each step in a multi-phased production...

Read

Topics:

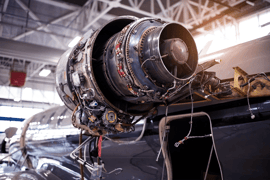

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

What Medical Device Manufacturers Need From Surface Cleanliness Testing

Quality tests during medical device production need to check a lot of boxes for manufacturers. Testing must increase confidence in product reliability in order to be worthwhile to manufacturers. What’s more, that confidence needs to be measurable and reportable because companies cannot tolerate...

Read

Topics:

Reliable and Efficient Manufacturing: Strategies You Can Use Now

Today, manufacturing requires a paradigm shift from reactionary whack-a-mole problem correction to taking a holistic approach. The mutually reliant elements of manufacturing are interwoven in both obvious and invisible ways. From supply chain communication to equipment dependability and from ...

Read

Topics:

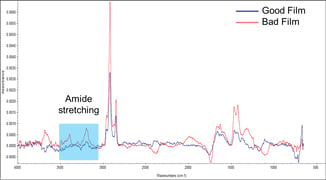

Using Data to Improve Ink Adhesion to Polymer Film

One of the most frustrating aspects of experiencing a problem in manufacturing isn't necessarily the issue itself, but rather, it's the difficulty of accurately determining and communicating what the problem actually is.

Read

Topics:

Controlling Parts Washing Methods for Medical Components

Cleanliness is next to production standardization requirements for medical device manufacturers (as the old saying goes). Devices built to be inserted within the human body understandably need to meet the highest cleanliness standards. Companies in this industry have already known what many of us...

Read

Topics:

The Dangers of Missing Vital Surface Quality Information in Production

A major problem for manufacturers is the problem of sensitivity. There is a rampant lack of sensitivity to material surfaces for companies across every manufacturing industry. Granted, it’s not easy to test surface quality to predict the outcomes of common manufacturing processes like adhesive...

Read

Topics:

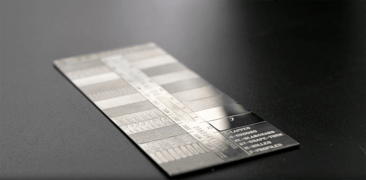

Proposed ASTM Standard Will Ease the Pain of Manufacturers

An exciting development is taking place to make surface quality and cleanliness inspection technology more available to all manufacturers. We have collaborated with ASTM International and other stakeholders to craft a revision to establish a standard use of handheld goniometers in production...

Read

Topics:

Study Proves the Surface Analyst is Dependable for Process Control

One of our favorite services we provide to manufacturers is to help optimize surface preparation techniques for their particular materials and products. It’s our specialty and one of our biggest passions. We feel so strongly about it because we know that if you, as a manufacturer, are able to...

Read

Topics:

How to Get the Most Out of Your Vacuum Plasma Treatment

Vacuum plasma is the treatment method of record for many manufacturers. Not only because it is a legacy technology proven useful over many, many decades but because it can be particularly effective at creating chemically reactive surfaces of various geometries that need to be bonded, coated,...

Read

Topics:

Cleaning Strategies for Great Adhesion

Cleanliness in manufacturing gains avid devotees all the time. Once the importance of cleanliness is grasped, it’s nearly impossible to think about manufacturing processes without considering the pervasive impact cleanliness has on every aspect and feature of the process.

Read

Topics:

Plasma Treatment for Complete and Reliable Cleaning with Richard Burke

At IPC APEX 2020 in San Diego, we wanted to explore the ways that electronics manufacturers, who encapsulate their circuit boards with a conformal coating, are cleaning their boards. What are the benefits to their current processes, and what are some things manufacturers could learn to make their...

Read

Topics:

The Tools & Skills to Address Adhesion Problems in Production

When adhesion issues become apparent in a manufacturing process, they can seem to come out of nowhere. When coatings on circuit boards delaminate and cause shorts, when automotive glass doesn’t properly seal and moisture is let through, or when implantable medical devices aren’t meeting cleanliness...

Read

Topics:

New Solutions to Address Adhesion Failures in Manufacturing

In order to create predictable adhesion outcomes in manufacturing, precision is key. When thinking about the success of a bonding, printing, coating, sealing, painting or cleaning application, manufacturers need a new perspective. Manufacturers need an approach that considers the entire adhesion...

Read

Topics:

How to Ensure a Manufacturing Surface is Clean Enough for Adhesion

Cleanliness and adhesion go hand-in-hand. If you’re looking for an adhesion process to be successful, you are also absolutely interested in cleaning the materials involved in the application. To get the most out of your cleaning operations, it’s imperative to know three things: What does clean...

Read

Topics:

How Surface Quality Devices Can Validate Adhesion Specs

Regulatory specifications in manufacturing exist to ensure that the highest quality, safest, and most useful products are created. These are devised internally through research and development testing to meet customer demands and through external regulatory bodies to protect consumers and public...

Read

Topics:

4 Manufacturing Process Gaps that Create Adhesion Problems

Process gaps emerge in production processes any time manufacturers lack all the information they need to make decisions that will prevent or solve adhesion problems. Often, these gaps result from oversights; however, they can also exist and be difficult to detect because they only become obvious...

Read

Topics:

Can a Surface Science Lab Ensure Adhesion in Manufacturing?

Manufacturers utilize research and design laboratories all the time. To scale new products up to the production line, years of toiling in testing labs are done to ensure that everything goes off without a hitch once production starts.

Read

Topics:

Secrets to Predicting Adhesion Failures in Production

When adhesion failure becomes apparent in manufacturing processes, it can seem to come out of nowhere. Very often, there is no problem until suddenly there is. It feels unpredictable, unavoidable, and like the best solution is to either eat the loss it brings or just hope it goes away as quickly...

Read

Topics:

Why a Surface Quality Inspection Process Ensures Adhesion

Manufacturing processes that involve bonding, coating, sealing, printing, painting, laminating, or cleaning need a metric to measure the surface quality of the materials involved. Without such a metric, it is impossible to predict whether the adhesion process will be successful or if it's on the...

Read

Topics:

Deck the Hulls: Preparing Ship Hulls for Coating and Painting

Manufacturing a product to withstand the environmental stresses of wind, rain, and sediment is challenging enough. But, when you add saltwater and wave action to the mix, the detrimental threat of corrosion increases significantly. A coating adhesion test is important for quickly testing a surface...

Read

Topics:

.png?width=372&height=180&name=adhesion-failure%20(2).png)