The Hidden Variable in Surface Prep: The Human Factor

KEY TAKEAWAYS Manual surface preparation introduces significant variability. Even with identical materials and written instructions, operator technique can dramatically change surface outcomes. Human execution impacts adhesion more than many realize. Subtle differences in pressure, angle,...

Read

Topics:

Posts by Topic

Precision Surface Measurement Redefined: Quality Use Cases for BConnect

KEY TAKEAWAYS How BCMobile enables fast, accurate, and repeatable surface energy measurement outside the lab.This article explains how BCMobile combines patented Ballistic Deposition, top-down imaging, and machine learning to deliver reliable water contact angle measurements in real-world...

Read

Topics:

How to Control Additive Blooming in Polymer Films

Key Takeaways Additive blooming is a common and often hidden cause of adhesion, sealing, and printing failures in polymer films. Certain additives are designed to migrate, but uncontrolled migration can undermine surface treatments. Blooming is driven by molecular mobility, temperature,...

Read

Topics:

3 Things You Need to Control for Proper Adhesion

The “What,” “Way,” and “The Surface” Behind Reliable Surface Bonding In manufacturing environments where bonding, coating, printing, or sealing takes place, success is never accidental. Whether you’re assembling automotive interiors, medical devices, electronics, or aerospace composites, adhesion...

Read

Topics:

The Best Method of Controlling HMDS Use in Semiconductor Manufacturing

Key Takeaways Hexamethyldisilazane (HMDS) is essential for creating a hydrophobic wafer surface that enables strong photoresist adhesion during photolithography. The effectiveness of HMDS depends heavily on surface preparation, moisture removal, and controlled vapor deposition conditions. ...

Read

Topics:

Surface Treatment Methods: A Practical Guide for Manufacturers

Key Takeaways Effective surface treatment is essential for strong, predictable adhesion in bonding, coating, printing, and sealing processes. Each treatment method has distinct advantages, limitations, and material compatibility considerations. Monitoring chemical surface condition is as important...

Read

Topics:

Is Roughness as Important as Surface Cleanliness to Adhesion?

Key Takeaways Surface roughness alone does not determine adhesion performance. Many benefits attributed to roughening actually come from unintentional cleaning during surface prep. Adhesion depends primarily on the chemical condition of the top one to five molecular layers. Surface aging and...

Read

Topics:

How to Measure Surface Tension

Key Takeaways Surface tension describes the molecular forces that determine how liquids interact with solids and directly affects adhesion, coating, and wetting performance. Measuring surface tension provides predictive insight into product reliability and process control. Dynamic surface tension...

Read

Topics:

The Cost of Poor Quality in Manufacturing and How Brighton Science Helps Stop It Before It Starts

In today’s fast-paced manufacturing environment, quality issues are more than just operational setbacks; they’re financial liabilities. The Cost of Poor Quality (COPQ) refers to the total financial burden a company incurs due to substandard products, inefficient processes, or rework.At Brighton...

Read

Topics:

What is the Difference Between Surface Free Energy and Surface Energy?

Key Takeaways Surface free energy and surface energy are interchangeable terms in manufacturing contexts; both describe the energy available at a material’s surface to enable interactions such as bonding, coating, printing, and cleaning. Surface energy has two components, dispersive and polar....

Read

Topics:

What is the Difference Between Surface Tension and Surface Energy

Key Takeaways: Surface tension describes the attractive forces between molecules at the surface of a liquid, while surface energy describes the same phenomenon at the surface of a solid. Both are expressions of intermolecular attraction, which determines whether two materials will adhere...

Read

Topics:

Invisible Problems, Measurable Solutions: A New Approach to Mold Maintenance

At PolyCon 2025 in Milwaukee, Brighton Science unveiled a breakthrough approach to mold maintenance—one that makes invisible surface problems visible and measurable. The session, “Invisible Problems, Measurable Solutions,” was led by Kaitlin Carroll, Customer Success Manager at Brighton Science....

Read

Topics:

What are Surfactants and How Do They Impact Surface Tension?

Key Takeaways: Surfactants are chemical compounds that lower a liquid's surface tension, allowing it to spread and interact with solids more easily. They are essential ingredients in cleaners, coatings, adhesives, and inks, but residual surfactants left behind can contaminate surfaces and weaken...

Read

Topics:

The Water Break Test as a Surface Measurement Gauge

Key Takeways The water break test is a simple, traditional method for assessing surface cleanliness, but it is subjective and limited in precision. It only detects hydrophobic contaminants and cannot quantify surface energy or detect hydrophilic residues such as surfactants. Because results are...

Read

Topics:

Silicone Contamination: The Problem You Don’t Know You Have

Most engineers expect failures to trace back to obvious causes, a material defect, an operator mistake, or a process error. But sometimes the culprit is hiding in plain sight: silicone contamination.

Read

Topics:

How Surface Measurements Help Medical Device Makers Avoid Delays

Medical Devices Face Unique Regulatory Pressures — and Surface Quality Plays a Bigger Role Than You Think Product reliability isn't optional in the medical device industry; it’s a regulatory requirement. Manufacturers must meet a growing number of global quality standards, from FDA regulations to ...

Read

Topics:

From Innovation to Standard: How Water Contact Angle Became the Surface Readiness Benchmark

A Common Language for an Uncommon Challenge One of the biggest barriers in global manufacturing is the lack of a shared language for surface quality. Engineering, operations, and suppliers often rely on guesswork or legacy tests.

Read

Topics:

How to Validate the Cleanliness of Optics (and Why It Matters More Than You Think)

In the world of optics, even a tiny speck of contamination can ruin a product. Whether you’re in precision manufacturing, medical imaging, or aerospace components, surface cleanliness isn’t just a box to check—it’s the foundation of performance and reliability.

Read

Topics:

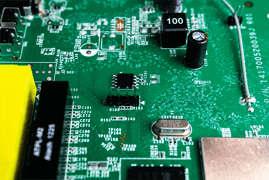

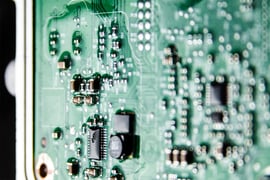

Ensuring Conformal Coating Reliability with Surface Intelligence

The Crucial Role of Conformal Coatings in Electronics Electronic components are the backbone of modern technology, from implantable medical devices and navigational equipment to sensor packages in cars and everyday cell phones. These delicate and exposed pieces are vulnerable to various...

Read

Topics:

Speed vs. Quality: How Manufacturing Sectors Balance Risk, Cost, and Innovation

In every manufacturing environment, there's one constant tension: how to move fast without breaking things. Whether you're building airplanes, cars, consumer electronics, or medical devices, the same tradeoff exists: production speed versus product quality.

Read

Topics:

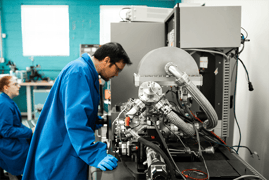

Comprehensive Guide to Understanding X-ray Photoelectron Spectroscopy (XPS) for Surface Analysis

X-ray photoelectron spectroscopy (XPS) is a sensitive surface analysis technique with broad applications across numerous industries. Beyond its fundamental role in materials characterization, XPS can provide critical information to solve real-world material challenges. With the help of Rose...

Read

Topics:

Environmental Silicone: Detection, Control, and Impact on Adhesion in Manufacturing

Silicone contamination is a huge problem in many painting and bonding applications. It’s impossible to see, hard to remove, and it creeps in unseen like a ghost. Where the harm it can cause is recognized, businesses go to great lengths to clean surfaces and exclude potential sources of...

Read

Topics:

Turn Complaints into Customer Satisfaction & Loyalty: Why Surface Chemistry Knowledge Matters

Imagine this: manufacturers and suppliers of cleaning solutions, coatings, adhesives, inks, and more receive countless customer calls daily. The common thread? Disappointment. Customers report their products aren't performing as expected – the paint isn't adhering, the adhesive bond is failing, or...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Contact Angle Goniometer 101: Guide to Measuring Contact Angle

Have you wondered why some paints or coatings adhere effortlessly while others leave blisters or bubbles? The answer lies in wettability, the intricate dance between a liquid and a surface governed by a powerful principle known as contact angle. And measuring this microscopic tango? That's where...

Read

Topics:

Fundamentals of Adhesion Science & Why 3 Molecular Layers Matter

Adhesion is crucial in microscopic and macroscopic worlds, yet it is an often-overlooked force. Adhesion acts as the invisible glue that unites objects, both massive and minute. Adhesion allows us to construct monumental structures like bridges, buildings, and airplanes. It enables us to glue wood...

Read

Topics:

4 Common Factors that Impact Conformal Coating Adhesion

The widespread use of electronics in all manufacturing sectors has presented distinct difficulties. Manufacturers are responsible for safeguarding these electronic devices in harsh conditions that render electronics susceptible to even the slightest traces of moisture, particles, and environmental ...

Read

Topics:

How Knowledge Sharing in Bonding Processes Drives Enterprise Success

Wind turbines have a problem: their giant blades fail more often than anticipated. Research on the issue, reported in the journal Materials, notes an average of 3,800 failures each year. Many of these result from adhesive bonding defects, which should be addressed and prevented through improved...

Read

Topics:

Maximize Manufacturing Excellence: Harness the Potential of Surface Quality Verification and Certification

In manufacturing, surfaces hold immense significance, and their value can be traced back to the inception of the Federal Aviation Administration (FAA) during the 20th century. The establishment of the FAA emerged as a response to mounting concerns surrounding quality control and the occurrence of...

Read

Topics:

Surface Inspection 101: A Visual Guide to the Surface Analyst, Water Break Tests, and Dyne Ink

In the manufacturing industry, it is crucial to meet certain surface preparation requirements in order to ensure the safety and reliability of products. Various tests have been developed to determine if these requirements are being met and if the cleaning process has been effective enough to...

Read

Topics:

Demystifying Dyne Levels: Understanding and Measuring Surface Quality

The evaluation of material surfaces in terms of quality has long relied on dyne testing. Despite their drawbacks, such as subjectivity, imprecision, damage to surfaces, and safety risks for users, dyne tests have remained popular among manufacturers due to their wide availability and affordability....

Read

Topics:

Non-Destructive Alternative to Dyne Testing for Reliable Quality Control

Dyne solutions have been the most common method of quality-checking material surface cleanliness for decades. Their ubiquity and low cost have led them to be heavily relied upon by manufacturers even though they are imprecise, destructive to surfaces, and harmful to the user. The science behind...

Read

Topics:

Guaranteeing Anti-fog Coating Application on Automotive Headlights

The competitive nature of the automotive industry requires manufacturers to engineer the ideal product; failures, no matter how small, are unacceptable and can bring heavy consequences.

Read

Topics:

Teflon: More Than Just Pots and Pans

Teflon is a household name that commonly invokes images of eggs sizzling on a skillet, spatulas flipping pancakes, or rice steaming in a pan. But there is much more to this magical non-stick coating.

Read

Topics:

How to Measure Contact Angle on Convex and Concave Surfaces

Historically, accurately measuring contact angles on concave and convex surfaces has been a challenge. The typical method used to measure contact angle on these types of surfaces has been with abenchtop goniometer. The challenges arise from how goniometers measurecontact angle—from a horizontal...

Read

Topics:

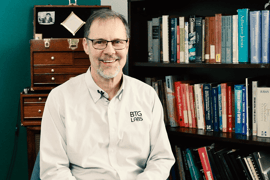

Meet Brighton Science's Chief Scientist, Giles Dillingham

A Deep History in Materials Science Founder and Chief Scientist of Brighton Science, Dr. Giles Dillingham's fascination with the connections between the invisible (the molecular structure of the world around us) and the perceivable (the properties and behavior of materials and objects) stems from a...

Read

Topics:

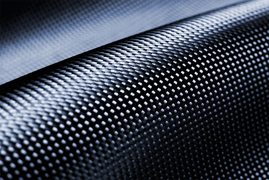

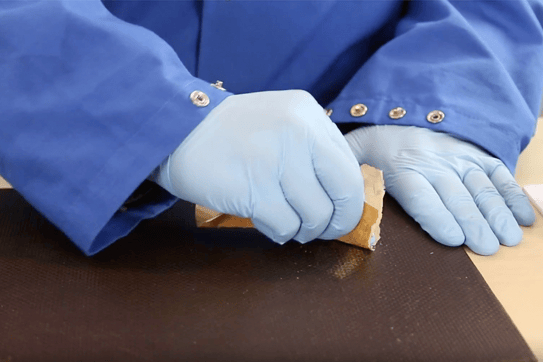

Surface Preparation for Primer Coating of Composites in Aerospace Applications

Achieving a flawless, long-lasting paint job on an aircraft is a complex undertaking. This multi-stage process starts well before the final coat graces the wings and tail. Components are meticulously molded, prepared (often involving multiple steps), assembled, and then coated with primers and...

Read

Topics:

Surface Measurements Help Coating and Plating Suppliers Guarantee Quality

Automotive supply chains are complex. Nearly 78 million vehicles were manufactured in 2020. Each vehicle may have upwards of 30,000 individual parts. Automotive original equipment manufacturers (OEMs) need to manage billions of parts annually. If any of these parts fail, vehicle performance is...

Read

Topics:

Why Knowing Water Contact Angle is Important for Successful Adhesive Performance

Adhesives are an integral part of modern manufacturing, but choosing the right adhesive is only one part of the equation. It’s well known that you won’t get a reliable bond with an adhesive if you just slap the adhesive onto your material without doing anything to prepare that surface. What ISN’T...

Read

Topics:

How to Prevent Coating Failure and Corrosion in Polymeric Materials

These days, if you see a painted product, it is likely a polymer-based coating providing a striking and powerful barrier between the underlying material and elements in the atmosphere that want to corrode that material. Polymer coating technology has advanced tremendously in the last decade....

Read

Topics:

Topcoat to Primer Surface Reliability for Aircraft Painting

Adhesion problems don’t have a preference when it comes to the kind of damage they cause. Whether the end result is structural or cosmetic, adhesion-related failure headaches for manufacturers abound. One of the most crucial aesthetic operations for aircraft OEMs is the topcoat of paint, although...

Read

Topics:

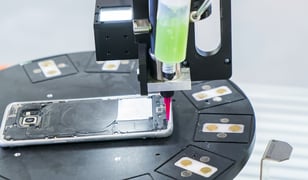

Better Consumer Electronics Reliability: Coatings and Adhesives

In a recent study conducted by Instrumental, the top ten most common manufacturing defects were examined. The number one defect that manufacturers fight against is a deficiency in glue.

Read

Topics:

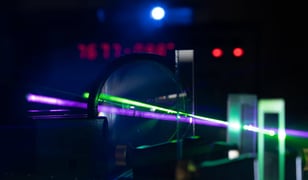

Surface Preparation for Reliable Optical Coatings in Photonics Manufacturing

Coatings are an indispensable part of manufacturing photonics. The coatings help determine the most basic functionality of the lenses they are applied to. How much light passes through, what happens to that light when it passes through the lens, does some light get absorbed, and are some spectral...

Read

Topics:

Ensuring the Durability of Oleophobic Coatings on Consumer Tech

Today, we're much more aware of the surfaces we touch and the potential unseen threats that linger on them. This focus on surface interaction isn't new for manufacturers, who've long considered how surfaces interact with our skin and the environment. Think about it – the simple act of touching...

Read

Topics:

How to Know if Hydrophilic Coatings on Medical Devices Provide the Necessary Comfort for Patients

Comfort is more than just a nice thing to hope for when it comes to medical devices like tubing, catheters and stents that are implanted into the human body. Comfort, in this instance, refers to the absence of pain. Having a piece of plastic or metal inserted into your body is never going to feel...

Read

Topics:

Coatings on Car Sensors and Why We Don’t Have Driverless Cars Yet

Our relationship with our vehicles may have changed in the past few months, with the idea of commuting to work looking more like a shuffle to the desk across the room rather than a drive to the office across town. However, cars have not dropped in prominence in our society. With health risks now...

Read

Topics:

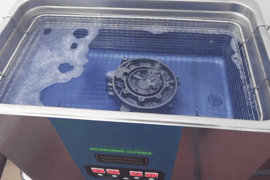

Controlling Parts Washing Methods for Medical Components

Cleanliness is next to production standardization requirements for medical device manufacturers (as the old saying goes). Devices built to be inserted within the human body understandably need to meet the highest cleanliness standards. Companies in this industry have already known what many of us...

Read

Topics:

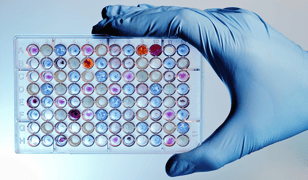

The Best Way to Verify Medical Diagnostics Coatings

The biomedical industry runs on testing. Testing is at the heart of meeting extensive requirements to ensure healthcare practices and facilities are safe. A kind of testing that has been on all of our minds lately is the kind of testing that analyzes the presence of diseases. Often these tests...

Read

Topics:

How to Protect Overmolded Connectors for Medical Devices

Protective coverings are part and parcel of our lives these days. For industries reliant upon electronic components and connectors, protective coverings in the form of polymeric over-molding encapsulation need to remain sealed and impervious to the environment.

Read

Topics:

Cleaning Strategies for Great Adhesion

Cleanliness in manufacturing gains avid devotees all the time. Once the importance of cleanliness is grasped, it’s nearly impossible to think about manufacturing processes without considering the pervasive impact cleanliness has on every aspect and feature of the process.

Read

Topics:

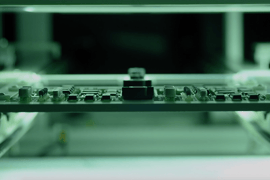

Why Surface Cleanliness is Crucial for Electronic PCBs

Defining “clean” is actually more complicated than it sounds. Cleanliness can be in the eye of the beholder (I mean, we all had a college roommate who swore they were tidy, but let’s be honest…), and it can also be calculated and precisely managed to the nth degree. In regard to PCB cleanliness for

Read

Topics:

The 3 Crucial Elements for High-Performance Adhesion in Manufacturing

Excellent adhesion relies on the manufacturer’s ability to understand and control three distinct yet interrelated elements. In manufacturing, adhesive bonding takes many forms, but the fundamental principles of adhesion are always the same. Even if the application is metal joint welding, Parylene...

Read

Topics:

Best-practice Surface Preparation Processes for New Products

New Product Development is an essential component to the successful growth of companies that always challenge themselves to improve and innovate. Getting this design stage right is pivotal in that it sets in motion everything the product will be and how well it will perform.

Read

Topics:

How to Ensure a Manufacturing Surface is Clean Enough for Adhesion

Cleanliness and adhesion go hand-in-hand. If you’re looking for an adhesion process to be successful, you are also absolutely interested in cleaning the materials involved in the application. To get the most out of your cleaning operations, it’s imperative to know three things: What does clean...

Read

Topics:

Can a Surface Science Lab Ensure Adhesion in Manufacturing?

Manufacturers utilize research and design laboratories all the time. To scale new products up to the production line, years of toiling in testing labs are done to ensure that everything goes off without a hitch once production starts.

Read

Topics:

Deck the Hulls: Preparing Ship Hulls for Coating and Painting

Manufacturing a product to withstand the environmental stresses of wind, rain, and sediment is challenging enough. But, when you add saltwater and wave action to the mix, the detrimental threat of corrosion increases significantly. A coating adhesion test is important for quickly testing a surface...

Read

Topics:

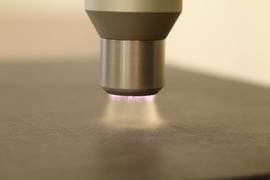

Surface Treatment Processes: Flame Treatment

Flame treatment is a surface activation treatment process used to chemically modify a surface for better adhesion. This process is typically used on low-energy surfaces that can be difficult to adhere to, such as plastics and composites. The treatment is also very gentle, posing low risk to the...

Read

Topics:

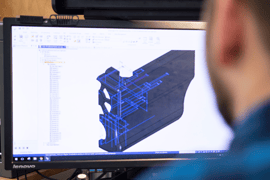

Inside Brighton Science's Lab: Advanced Materials and Process Experts

Brighton Science Lab Capabilities The history of Brighton Science (formerly BTG Labs) is rooted in adhesion research. Originally a development lab, Brighton Science specialized in plasma polymerized coatings. The engineers worked with coatings containing corrosion-resistant and anti-microbial...

Read

Topics:

.png?width=372&height=180&name=adhesion-failure%20(2).png)

.png?width=372&height=180&name=Cleaning%20Processes%20(Blog).png)