The Hidden Variable in Surface Prep: The Human Factor

KEY TAKEAWAYS Manual surface preparation introduces significant variability. Even with identical materials and written instructions, operator technique can dramatically change surface outcomes. Human execution impacts adhesion more than many realize. Subtle differences in pressure, angle,...

Read

Topics:

Posts by Topic

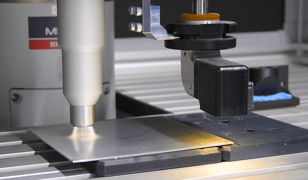

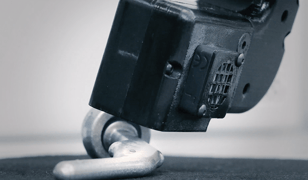

Precision Surface Measurement Redefined: Quality Use Cases for BConnect

KEY TAKEAWAYS How BCMobile enables fast, accurate, and repeatable surface energy measurement outside the lab.This article explains how BCMobile combines patented Ballistic Deposition, top-down imaging, and machine learning to deliver reliable water contact angle measurements in real-world...

Read

Topics:

3 Things You Need to Control for Proper Adhesion

The “What,” “Way,” and “The Surface” Behind Reliable Surface Bonding In manufacturing environments where bonding, coating, printing, or sealing takes place, success is never accidental. Whether you’re assembling automotive interiors, medical devices, electronics, or aerospace composites, adhesion...

Read

Topics:

Is Roughness as Important as Surface Cleanliness to Adhesion?

Key Takeaways Surface roughness alone does not determine adhesion performance. Many benefits attributed to roughening actually come from unintentional cleaning during surface prep. Adhesion depends primarily on the chemical condition of the top one to five molecular layers. Surface aging and...

Read

Topics:

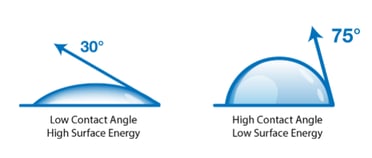

How to Measure Surface Tension

Key Takeaways Surface tension describes the molecular forces that determine how liquids interact with solids and directly affects adhesion, coating, and wetting performance. Measuring surface tension provides predictive insight into product reliability and process control. Dynamic surface tension...

Read

Topics:

What is the Difference Between Surface Free Energy and Surface Energy?

Key Takeaways Surface free energy and surface energy are interchangeable terms in manufacturing contexts; both describe the energy available at a material’s surface to enable interactions such as bonding, coating, printing, and cleaning. Surface energy has two components, dispersive and polar....

Read

Topics:

What is the Difference Between Surface Tension and Surface Energy

Key Takeaways: Surface tension describes the attractive forces between molecules at the surface of a liquid, while surface energy describes the same phenomenon at the surface of a solid. Both are expressions of intermolecular attraction, which determines whether two materials will adhere...

Read

Topics:

Invisible Problems, Measurable Solutions: A New Approach to Mold Maintenance

At PolyCon 2025 in Milwaukee, Brighton Science unveiled a breakthrough approach to mold maintenance—one that makes invisible surface problems visible and measurable. The session, “Invisible Problems, Measurable Solutions,” was led by Kaitlin Carroll, Customer Success Manager at Brighton Science....

Read

Topics:

What are Surfactants and How Do They Impact Surface Tension?

Key Takeaways: Surfactants are chemical compounds that lower a liquid's surface tension, allowing it to spread and interact with solids more easily. They are essential ingredients in cleaners, coatings, adhesives, and inks, but residual surfactants left behind can contaminate surfaces and weaken...

Read

Topics:

The Water Break Test as a Surface Measurement Gauge

Key Takeways The water break test is a simple, traditional method for assessing surface cleanliness, but it is subjective and limited in precision. It only detects hydrophobic contaminants and cannot quantify surface energy or detect hydrophilic residues such as surfactants. Because results are...

Read

Topics:

How Surface Measurements Help Medical Device Makers Avoid Delays

Medical Devices Face Unique Regulatory Pressures — and Surface Quality Plays a Bigger Role Than You Think Product reliability isn't optional in the medical device industry; it’s a regulatory requirement. Manufacturers must meet a growing number of global quality standards, from FDA regulations to ...

Read

Topics:

From Innovation to Standard: How Water Contact Angle Became the Surface Readiness Benchmark

A Common Language for an Uncommon Challenge One of the biggest barriers in global manufacturing is the lack of a shared language for surface quality. Engineering, operations, and suppliers often rely on guesswork or legacy tests.

Read

Topics:

How to Validate the Cleanliness of Optics (and Why It Matters More Than You Think)

In the world of optics, even a tiny speck of contamination can ruin a product. Whether you’re in precision manufacturing, medical imaging, or aerospace components, surface cleanliness isn’t just a box to check—it’s the foundation of performance and reliability.

Read

Topics:

Speed vs. Quality: How Manufacturing Sectors Balance Risk, Cost, and Innovation

In every manufacturing environment, there's one constant tension: how to move fast without breaking things. Whether you're building airplanes, cars, consumer electronics, or medical devices, the same tradeoff exists: production speed versus product quality.

Read

Topics:

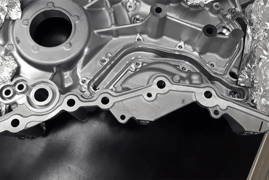

Enhancing Automotive Manufacturing with Surface Intelligence

The Evolution of Automotive Materials and Their Challenges The automotive industry is constantly evolving, with manufacturers adopting advanced materials to improve strength, fuel efficiency, and durability while reducing weight and cost. Traditional materials like steel and iron are increasingly...

Read

Topics:

Environmental Silicone: Detection, Control, and Impact on Adhesion in Manufacturing

Silicone contamination is a huge problem in many painting and bonding applications. It’s impossible to see, hard to remove, and it creeps in unseen like a ghost. Where the harm it can cause is recognized, businesses go to great lengths to clean surfaces and exclude potential sources of...

Read

Topics:

The High Cost of Molding Defects: Protect Your Bottom Line

Imagine crafting a colossal mold, a behemoth capable of shaping fiberglass and composites into the intricate contours of a plane wing, the sleek hull of a boat, or even the entire body of a bus. It's a monumental task, requiring months of meticulous preparation and planning. As you gear up to start...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Navigating the Solvent Switch: A Sustainable Future for Parts Cleaning

Manufacturers who use solvent-based industrial parts cleaning processes must find alternative methods. Solvent-based cleaning processes use chemicals that emit or release Volatile Organic Compounds (VOCs). These are coming under increased scrutiny due to their harmful effects on health and the...

Read

Topics:

Contact Angle Goniometer 101: Guide to Measuring Contact Angle

Have you wondered why some paints or coatings adhere effortlessly while others leave blisters or bubbles? The answer lies in wettability, the intricate dance between a liquid and a surface governed by a powerful principle known as contact angle. And measuring this microscopic tango? That's where...

Read

Topics:

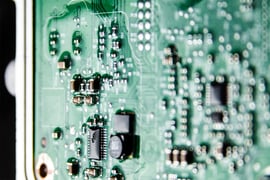

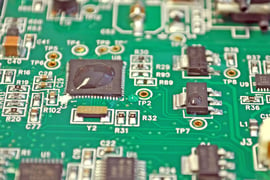

4 Common Factors that Impact Conformal Coating Adhesion

The widespread use of electronics in all manufacturing sectors has presented distinct difficulties. Manufacturers are responsible for safeguarding these electronic devices in harsh conditions that render electronics susceptible to even the slightest traces of moisture, particles, and environmental ...

Read

Topics:

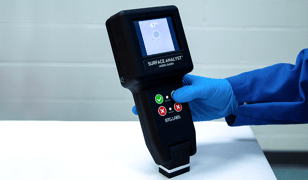

Surface Inspection 101: A Visual Guide to the Surface Analyst, Water Break Tests, and Dyne Ink

In the manufacturing industry, it is crucial to meet certain surface preparation requirements in order to ensure the safety and reliability of products. Various tests have been developed to determine if these requirements are being met and if the cleaning process has been effective enough to...

Read

Topics:

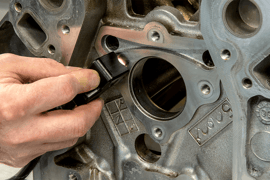

Contact Angle Analysis: Sealing Surface of Aluminum Castings

Surface Quality Requirements of Aluminum Castings Manufacturers widely utilize aluminum castings as the most successful way to create aluminum parts. However, this process can involve inorganic contaminants on the surface, which interfere with potential bonding, sealing, or coating. Scientists at...

Read

Topics:

Demystifying Dyne Levels: Understanding and Measuring Surface Quality

The evaluation of material surfaces in terms of quality has long relied on dyne testing. Despite their drawbacks, such as subjectivity, imprecision, damage to surfaces, and safety risks for users, dyne tests have remained popular among manufacturers due to their wide availability and affordability....

Read

Topics:

Non-Destructive Alternative to Dyne Testing for Reliable Quality Control

Dyne solutions have been the most common method of quality-checking material surface cleanliness for decades. Their ubiquity and low cost have led them to be heavily relied upon by manufacturers even though they are imprecise, destructive to surfaces, and harmful to the user. The science behind...

Read

Topics:

Surface Energy Measurement is the Key to Process Control and High Performance

When manufacturing companies take adhesion seriously, they can significantly improve their ability to achieve their business goals. The key is to take a strategic look at adhesion processes early in product development.

Read

Topics:

How to Fix Common Causes of Adhesion Problems

Manufacturers often have a large blind spot regarding the causes of adhesion problems. This blind spot makes it impossible to solve these problems and generates frustration and loss rather than productivity and adhesion success. Taking the blinders off and taking on adhesion failure at its...

Read

Topics:

Guess the Contact Angle: IPA Wiped Composite Material

This 'Guess the Contact Angle' video is the first of our next series of videos focusing on how contact angle changes when a composite surface is cleaned or treated in various ways. The contact angle featured in this demo is formed by a water droplet deposited using the handheld Surface Analyst on...

Read

Topics:

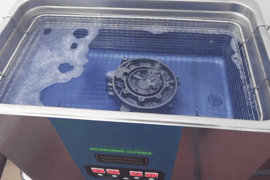

The Best Way to Qualify a Wash Method for Your Manufacturing Process

Parts washers are heavy-duty, hardworking machines that have become irreplaceable staples in automotive andmachined part manufacturing processes. As manufacturing processes have become more sophisticated, the industries using parts washers have expanded to includenot only industrial metals and...

Read

Topics:

Surface Analyst Diagnoses Critical Cleaning Issue of Defense Weaponry Components

Brighton Science's Surface Analyst was featured in a Finishing & Coating article where Hubbard-Hall used the handheld technology to diagnose a $1 million dollar problem for a manufacturer that extrudes aluminum tubes as part of two individual missile systems: an armor piercing air to surface...

Read

Topics:

Why You Should Rethink Your Manufacturing Cleaning Process

In manufacturing, a final assembly is only as reliable as its constituent parts, the bonding or joining method used to hold them together, or the coating method used for corrosion protection and/or the final aesthetic touch. In order to guarantee the strength and successful performance of a...

Read

Topics:

Why You Should Implement a Surface Cleanliness Specification Using Contact Angle

When cleaning invisible contaminants from a surface, you may ask yourself, "How do I know when the surface is clean, or how clean, is clean enough?" These are common questions that product development teams ask when developing new products that require surfaces to be thoroughly cleaned in order to...

Read

Topics:

Guess the Contact Angle: Plasma Treated Aluminum

So far in our Guess the Contact Angle Series, we have brought you three videos demonstrating how contact angle changes depending on the state of the material surface: Contact angle measurement on a piece of aged, 'as is' aluminum Contact angle measurement on aluminum after cleaning it with an IPA...

Read

Topics:

Why Automotive Glass Bonding Recalls Should be a Thing of the Past

Automotive glass is a technological marvel. Despite its clarity, much of how it's manufactured is unseen by the average driver. Silica compounds, tempering, and lamination all combine to create one of the most critical components of today’s motor vehicles. Unfortunately, though, things periodically...

Read

Topics:

Guess the Contact Angle: Abraded Aluminum

So far, in our Guess the Contact Angle Series, we have brought you two videos: the first one shows the Surface Analyst taking a contact angle measurement on a piece of aged, 'as is' aluminum. The second video asks you to guess the contact angle after we took the same piece of aluminum but cleaned...

Read

Topics:

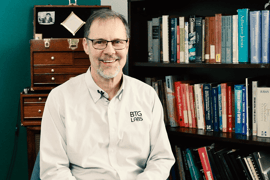

Meet Brighton Science's Chief Scientist, Giles Dillingham

A Deep History in Materials Science Founder and Chief Scientist of Brighton Science, Dr. Giles Dillingham's fascination with the connections between the invisible (the molecular structure of the world around us) and the perceivable (the properties and behavior of materials and objects) stems from a...

Read

Topics:

Guess the Contact Angle: IPA Wiped Aluminum

As part of the Guess the Contact Angle series, we have brought you a new video that highlights best practices when cleaning material surfaces with IPA wipes and we will ask you to "guess" the contact angle measurement after the surface has been cleaned. The contact angle featured in this demo is...

Read

Topics:

Can Contact Angle Quantitatively Measure Total Surface Energy?

In an article published in the Journal of Adhesion Science and Technology, "Water Contact Angle as a Quantitative Measure of Total Polyethylene Surface Energy" Materials Scientists from Brighton Science (formerly BTG Labs) explain the validity of water contact angle as a measurement for total ...

Read

Topics:

How Manufacturers Can Optimize the Effectiveness of Plasma Activation

In last week’s blog post, Using Plasma for Surface Cleaning and Activation, Rose Roberts, Ph.D., Brighton Science's (formerly BTG Labs) Senior Custom Applications and Materials Engineer, discussed how to use plasma for the dual purposes of cleaning critical surfaces and activating critical surfaces...

Read

Topics:

Using Plasma for Surface Cleaning and Activation

This blog post is the first of a two-part series focusing on plasma. With the help of Rose Roberts, Ph.D., Senior Custom Applications and Materials Engineer, we will review plasma basics and discuss how plasma can be used for both cleaning and surface activation. We will also touch upon the...

Read

Topics:

Surface Measurements Help Coating and Plating Suppliers Guarantee Quality

Automotive supply chains are complex. Nearly 78 million vehicles were manufactured in 2020. Each vehicle may have upwards of 30,000 individual parts. Automotive original equipment manufacturers (OEMs) need to manage billions of parts annually. If any of these parts fail, vehicle performance is...

Read

Topics:

3 Things You Need to Know to Create Reliable Bonds With Laser Cleaning

Manufacturers are always looking to create stronger, more durable, reliable, and lightweight products in the automotive and aerospace sectors. In this pursuit, they’ve often upgraded and swapped out material systems for metal alloys with lower density, better temperature tolerance, and corrosion...

Read

Topics:

Quantifying the Effectiveness of High Volume Metal Cleaning in Fresh and Aged Baths

In today’s video, we will show you how to quantify the surface quality of metals when using fresh and aged baths. We will demonstrate how Water Contact Angle (WCA) measurements can provide feedback in less than two seconds on the effectiveness of your cleaning process and will enable you to improve...

Read

Topics:

Guess the Contact Angle: Aged 'as is' Aluminum

In today’s blog post, we are going to have a bit of fun using video to learn more about contact angles. We will show you a contact angle and will ask you to “guess” the contact angle measurement. The contact angle featured in this demo is formed by a water droplet deposited on a piece of ‘as is’...

Read

Topics:

Why Knowing Water Contact Angle is Important for Successful Adhesive Performance

Adhesives are an integral part of modern manufacturing, but choosing the right adhesive is only one part of the equation. It’s well known that you won’t get a reliable bond with an adhesive if you just slap the adhesive onto your material without doing anything to prepare that surface. What ISN’T...

Read

Topics:

10 Most Common Surface Quality Mistakes by Manufacturers

Manufacturers are constantly fighting against adhesion problems. Surfaces not sticking and adhesives not working is the daily reality facing manufacturers looking to make high-quality, reliable products. The daunting nature of the task of eliminating adhesion failure seems insurmountable and...

Read

Topics:

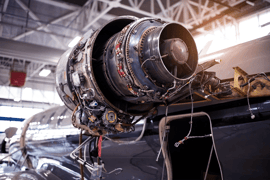

Topcoat to Primer Surface Reliability for Aircraft Painting

Adhesion problems don’t have a preference when it comes to the kind of damage they cause. Whether the end result is structural or cosmetic, adhesion-related failure headaches for manufacturers abound. One of the most crucial aesthetic operations for aircraft OEMs is the topcoat of paint, although...

Read

Topics:

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

Manufacturing Best Practices for Business Continuity Plans

The manufacturing industry has undergone unprecedented challenges in recent years, necessitating a fundamental re-evaluation of business continuity strategies. While economic downturns have historically presented obstacles, the complexities of today’s globalized and interconnected business...

Read

Topics:

What Medical Device Manufacturers Need From Surface Cleanliness Testing

Quality tests during medical device production need to check a lot of boxes for manufacturers. Testing must increase confidence in product reliability in order to be worthwhile to manufacturers. What’s more, that confidence needs to be measurable and reportable because companies cannot tolerate...

Read

Topics:

How to Get a Stronger Weld Through Cleaning

Even though we look around us and see plastic everywhere, in every shape and imaginable application, metals are still a more commonly used raw material in machined products. Metals are the legacy material of choice due to their strength and relative ease of bonding. However, advances in polymers...

Read

Topics:

Controlling Parts Washing Methods for Medical Components

Cleanliness is next to production standardization requirements for medical device manufacturers (as the old saying goes). Devices built to be inserted within the human body understandably need to meet the highest cleanliness standards. Companies in this industry have already known what many of us...

Read

Topics:

Single vs Multi-fluid Contact Angle Techniques Part 1: Surface energy and the attractions between substances

This is part one of a two-part series explaining the finer points of Brighton Science's approach to helping companies build reliability into their cleaning and adhesion processes through consultation and implementation of novel inspection equipment. These two articles are based on this technical...

Read

Topics:

Will New Hand Washing Practices Cause Problems for Manufacturing?

Like many industries during the COVID-19 crisis, manufacturing has had to make big changes, including scaling back its workforce, enforcing new and intensified hygiene standards, and taking a closer look at workplace cleanliness. Looking ahead to the permanent adjustments we’re all making, it’s...

Read

Topics:

Proposed ASTM Standard Will Ease the Pain of Manufacturers

An exciting development is taking place to make surface quality and cleanliness inspection technology more available to all manufacturers. We have collaborated with ASTM International and other stakeholders to craft a revision to establish a standard use of handheld goniometers in production...

Read

Topics:

How to Protect Overmolded Connectors for Medical Devices

Protective coverings are part and parcel of our lives these days. For industries reliant upon electronic components and connectors, protective coverings in the form of polymeric over-molding encapsulation need to remain sealed and impervious to the environment.

Read

Topics:

How to Get the Most Out of Your Vacuum Plasma Treatment

Vacuum plasma is the treatment method of record for many manufacturers. Not only because it is a legacy technology proven useful over many, many decades but because it can be particularly effective at creating chemically reactive surfaces of various geometries that need to be bonded, coated,...

Read

Topics:

Covid-19: Biological vs. Chemical Contamination in Manufacturing

Lately, the whole world has seen variations of the same conversation. Whether the discussion centers on N95 masks, toilet paper, hand sanitizer, disinfecting wipes, or what movies to watch while maintaining a safe social distance, the underlying concern is about cleanliness.

Read

Topics:

Cleaning Strategies for Great Adhesion

Cleanliness in manufacturing gains avid devotees all the time. Once the importance of cleanliness is grasped, it’s nearly impossible to think about manufacturing processes without considering the pervasive impact cleanliness has on every aspect and feature of the process.

Read

Topics:

Plasma Treatment for Complete and Reliable Cleaning with Richard Burke

At IPC APEX 2020 in San Diego, we wanted to explore the ways that electronics manufacturers, who encapsulate their circuit boards with a conformal coating, are cleaning their boards. What are the benefits to their current processes, and what are some things manufacturers could learn to make their...

Read

Topics:

History of Cleaning for Ideal Electronics Manufacturing with Mike Konrad

At IPC APEX 2020 in San Diego, we got the chance to sit down and chat with Mike Konrad from Aqueous Technologies and the Reliability Matters podcast, a show about the reliability of circuit assemblies.

Read

Topics:

Why Surface Cleanliness is Crucial for Electronic PCBs

Defining “clean” is actually more complicated than it sounds. Cleanliness can be in the eye of the beholder (I mean, we all had a college roommate who swore they were tidy, but let’s be honest…), and it can also be calculated and precisely managed to the nth degree. In regard to PCB cleanliness for

Read

Topics:

Best-practice Surface Preparation Processes for New Products

New Product Development is an essential component to the successful growth of companies that always challenge themselves to improve and innovate. Getting this design stage right is pivotal in that it sets in motion everything the product will be and how well it will perform.

Read

Topics:

How to Ensure a Manufacturing Surface is Clean Enough for Adhesion

Cleanliness and adhesion go hand-in-hand. If you’re looking for an adhesion process to be successful, you are also absolutely interested in cleaning the materials involved in the application. To get the most out of your cleaning operations, it’s imperative to know three things: What does clean...

Read

Topics:

Can a Surface Science Lab Ensure Adhesion in Manufacturing?

Manufacturers utilize research and design laboratories all the time. To scale new products up to the production line, years of toiling in testing labs are done to ensure that everything goes off without a hitch once production starts.

Read

Topics:

Optimizing your Metal Performance with the Surface Analyst

Manufacturers who work with metal and are concerned with metal performance are all too familiar with the obstacles that come along with coating, painting, bonding, printing, or sealing it. While the uses of metal in manufacturing are countless and exist in numerous industries, the common...

Read

Topics:

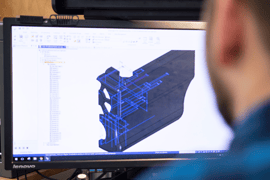

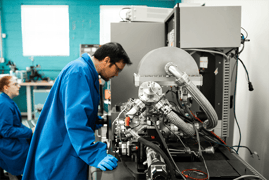

Inside Brighton Science's Lab: Advanced Materials and Process Experts

Brighton Science Lab Capabilities The history of Brighton Science (formerly BTG Labs) is rooted in adhesion research. Originally a development lab, Brighton Science specialized in plasma polymerized coatings. The engineers worked with coatings containing corrosion-resistant and anti-microbial...

Read

Topics:

CMH-17 Composite Materials Handbook: Validating Surface Preparation

Ongoing Advancements in the Field of Composite Materials Brighton Science (formerly BTG Labs) maintains an important connection to CMH-17, the Composite Materials Handbook. Brighton Science's special connection began in 2004 when Giles Dillingham, Founder and Chief Scientist, read that CMH-17...

Read

Topics:

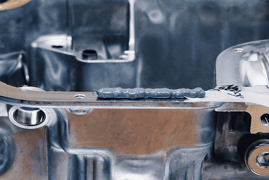

Ensuring Success for Automotive Formed-In-Place Gasket (FIPG) Sealing

Controlling Surface Condition in FIPG Application Increasingly, FIPG processes are replacing traditional gaskets for a variety of automotive applications, such as air filters, oil filters, door panels, and external engine parts. The advantages include cheaper material cost, higher throughput...

Read

Topics:

.png?width=372&height=180&name=adhesion-failure%20(2).png)