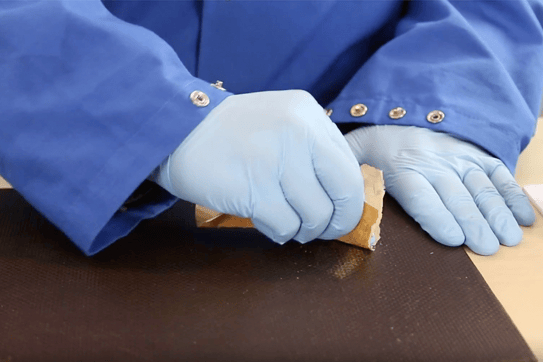

The Hidden Variable in Surface Prep: The Human Factor

KEY TAKEAWAYS Manual surface preparation introduces significant variability. Even with identical materials and written instructions, operator technique can dramatically change surface outcomes. Human execution impacts adhesion more than many realize. Subtle differences in pressure, angle,...

Read

Topics:

Posts by Topic

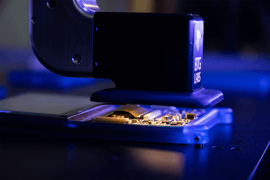

Precision Surface Measurement Redefined: Quality Use Cases for BConnect

KEY TAKEAWAYS How BCMobile enables fast, accurate, and repeatable surface energy measurement outside the lab.This article explains how BCMobile combines patented Ballistic Deposition, top-down imaging, and machine learning to deliver reliable water contact angle measurements in real-world...

Read

Topics:

What is Materials Science & Why is it Crucial for New Product Development?

Key Takeaways Materials science connects chemistry, physics, and engineering to explain how atomic and molecular structure drives real-world material performance. Material properties determine what products are possible, from aircraft and medical devices to consumer electronics. Technological...

Read

Topics:

Verification vs. Validation for Medical Device Quality Assurance

Key Takeaways Verification confirms that a medical device meets defined specifications and regulatory requirements. Validation confirms that a process consistently produces devices that meet user needs in real use conditions. FDA Quality System Regulation (QSR) requires validation when process...

Read

Topics:

How to Control Additive Blooming in Polymer Films

Key Takeaways Additive blooming is a common and often hidden cause of adhesion, sealing, and printing failures in polymer films. Certain additives are designed to migrate, but uncontrolled migration can undermine surface treatments. Blooming is driven by molecular mobility, temperature,...

Read

Topics:

3 Things You Need to Control for Proper Adhesion

The “What,” “Way,” and “The Surface” Behind Reliable Surface Bonding In manufacturing environments where bonding, coating, printing, or sealing takes place, success is never accidental. Whether you’re assembling automotive interiors, medical devices, electronics, or aerospace composites, adhesion...

Read

Topics:

The Best Method of Controlling HMDS Use in Semiconductor Manufacturing

Key Takeaways Hexamethyldisilazane (HMDS) is essential for creating a hydrophobic wafer surface that enables strong photoresist adhesion during photolithography. The effectiveness of HMDS depends heavily on surface preparation, moisture removal, and controlled vapor deposition conditions. ...

Read

Topics:

Surface Treatment Methods: A Practical Guide for Manufacturers

Key Takeaways Effective surface treatment is essential for strong, predictable adhesion in bonding, coating, printing, and sealing processes. Each treatment method has distinct advantages, limitations, and material compatibility considerations. Monitoring chemical surface condition is as important...

Read

Topics:

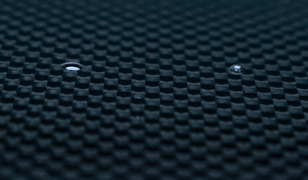

Is Roughness as Important as Surface Cleanliness to Adhesion?

Key Takeaways Surface roughness alone does not determine adhesion performance. Many benefits attributed to roughening actually come from unintentional cleaning during surface prep. Adhesion depends primarily on the chemical condition of the top one to five molecular layers. Surface aging and...

Read

Topics:

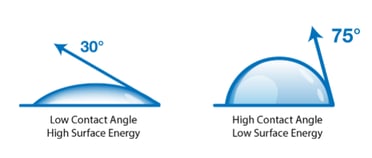

How to Measure Surface Tension

Key Takeaways Surface tension describes the molecular forces that determine how liquids interact with solids and directly affects adhesion, coating, and wetting performance. Measuring surface tension provides predictive insight into product reliability and process control. Dynamic surface tension...

Read

Topics:

What is the Difference Between Surface Free Energy and Surface Energy?

Key Takeaways Surface free energy and surface energy are interchangeable terms in manufacturing contexts; both describe the energy available at a material’s surface to enable interactions such as bonding, coating, printing, and cleaning. Surface energy has two components, dispersive and polar....

Read

Topics:

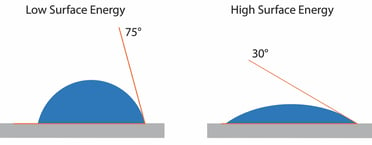

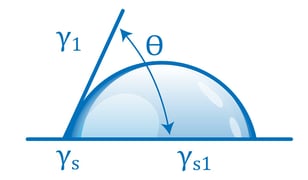

What is the Difference Between Surface Tension and Surface Energy

Key Takeaways: Surface tension describes the attractive forces between molecules at the surface of a liquid, while surface energy describes the same phenomenon at the surface of a solid. Both are expressions of intermolecular attraction, which determines whether two materials will adhere...

Read

Topics:

What are Surfactants and How Do They Impact Surface Tension?

Key Takeaways: Surfactants are chemical compounds that lower a liquid's surface tension, allowing it to spread and interact with solids more easily. They are essential ingredients in cleaners, coatings, adhesives, and inks, but residual surfactants left behind can contaminate surfaces and weaken...

Read

Topics:

The Water Break Test as a Surface Measurement Gauge

Key Takeways The water break test is a simple, traditional method for assessing surface cleanliness, but it is subjective and limited in precision. It only detects hydrophobic contaminants and cannot quantify surface energy or detect hydrophilic residues such as surfactants. Because results are...

Read

Topics:

From Innovation to Standard: How Water Contact Angle Became the Surface Readiness Benchmark

A Common Language for an Uncommon Challenge One of the biggest barriers in global manufacturing is the lack of a shared language for surface quality. Engineering, operations, and suppliers often rely on guesswork or legacy tests.

Read

Topics:

Beyond Surface Prep: How Manufacturers Are Using Water Contact Angle to Control Adhesion Quality

Introduction Adhesion failures are among the most common yet preventable issues in composite bonding, coatings, and sealants. Whether in aerospace, automotive, or medical manufacturing, poor surface preparation can lead to structural weaknesses, warranty claims, and costly rework. But what if the...

Read

Topics:

Bridging the Gap Between Data and Action in Manufacturing with BConnect

In the last decade, industries have increasingly recognized the importance of surface readiness as a critical factor in bonding processes. Yet, this understanding often fails to permeate every level of the organization, particularly among personnel directly working on manufacturing lines. Whether...

Read

Topics:

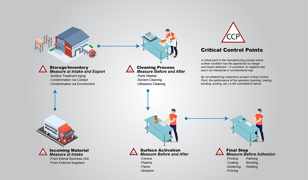

Managing Critical Control Points and Adhesion Failures with Next-Gen Technology

Bond failures remain a significant challenge for manufacturers, occurring on a large scale every week despite widespread awareness of the importance of surface readiness in bonding processes like sealing, coating, cleaning, and painting. Why? Because controlling adhesion throughout every...

Read

Topics:

The Hidden Factor in Product Performance: Why the Top Few Molecular Levels of a Surface are Critical to Product Reliability

Manufactured and assembled products almost always require adhesion or cleaning steps—whether bonding, coating, painting, or printing—which makes the quality of those surfaces essential to the product's final performance. Contrary to conventional assumptions, surfaces are highly variable and...

Read

Topics:

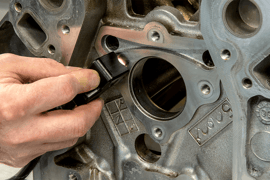

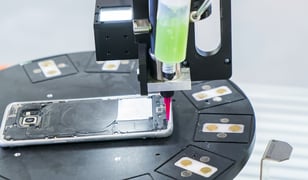

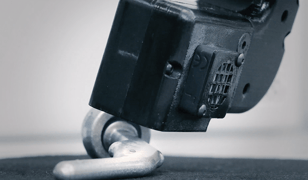

Ensuring Gasket Reliability: The Critical Role of Surface Quality in Formed-in-Place Gasket Applications

Formed-in-place gaskets (FIPG) have revolutionized sealing solutions across industries that require high-reliability seals. While there are many types of gaskets, a FIPG is created from a specific method where a liquid sealant, typically applied by an automated dispensing system, is dispensed...

Read

Topics:

Comprehensive Guide to Understanding X-ray Photoelectron Spectroscopy (XPS) for Surface Analysis

X-ray photoelectron spectroscopy (XPS) is a sensitive surface analysis technique with broad applications across numerous industries. Beyond its fundamental role in materials characterization, XPS can provide critical information to solve real-world material challenges. With the help of Rose...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Corona Treatment Concerns You Need to Take a Closer Look At

Disclaimer: This article is NOT about COVID-19; it is about a surface treatment process for better surface preparation and adhesion properties in manufacturing. If you're looking for information about cleaning, here's an article that discusses the difference between biological cleanliness and...

Read

Topics:

Unlock the Key to Successful Adhesive Bonding: What You Need to Know Beyond Adhesive Technical Data Sheets

Manufacturers are increasingly utilizing a greater number of adhesive materials as a joining technique in the construction of their products, and the importance of these uses is continuously increasing with each passing year. As a result, the consequences of adhesive bond failures are becoming more...

Read

Topics:

Contact Angle Goniometer 101: Guide to Measuring Contact Angle

Have you wondered why some paints or coatings adhere effortlessly while others leave blisters or bubbles? The answer lies in wettability, the intricate dance between a liquid and a surface governed by a powerful principle known as contact angle. And measuring this microscopic tango? That's where...

Read

Topics:

Sustainable Manufacturing: How to Overcome the Hidden Obstacles Using Post-Consumer Recycled Plastics (PCR)

Many businesses within the industrial sector are pushing for sustainable manufacturing initiatives, but one of the biggest challenges in sustainability is dealing with plastics and their disposal. Some leading manufacturers, including a number of automotive companies, are introducing a new...

Read

Topics:

Fundamentals of Adhesion Science & Why 3 Molecular Layers Matter

Adhesion is crucial in microscopic and macroscopic worlds, yet it is an often-overlooked force. Adhesion acts as the invisible glue that unites objects, both massive and minute. Adhesion allows us to construct monumental structures like bridges, buildings, and airplanes. It enables us to glue wood...

Read

Topics:

4 Common Factors that Impact Conformal Coating Adhesion

The widespread use of electronics in all manufacturing sectors has presented distinct difficulties. Manufacturers are responsible for safeguarding these electronic devices in harsh conditions that render electronics susceptible to even the slightest traces of moisture, particles, and environmental ...

Read

Topics:

How to Control Your Adhesive Process: Find the Critical Control Points

In today's highly competitive manufacturing environment, controlling the adhesive process is vital to ensuring product quality, consistency, and efficiency. Understanding the Critical Control Points (CCPs) within the adhesive process is essential for maintaining control and achieving desired...

Read

Topics:

On the Surface: An Overview of Surface Types and Measurement Challenges in Manufacturing

Of all the challenges manufacturers face, creating and optimizing critical surface processes for various materials can be very difficult. Traits such as location, size, shape, and texture can add to the challenge. The success of any critical surface process requires an in-line, fast, easy, and...

Read

Topics:

The Thought Behind our New Brighton Academy

Over the past decade, we have been told that our science is the cornerstone of our customer relationships. Whether you’ve been with us from the beginning or just recently joined the BConnect community, during your journey with us, we’ve likely shared our scientific insights with you. This may have...

Read

Topics:

How Knowledge Sharing in Bonding Processes Drives Enterprise Success

Wind turbines have a problem: their giant blades fail more often than anticipated. Research on the issue, reported in the journal Materials, notes an average of 3,800 failures each year. Many of these result from adhesive bonding defects, which should be addressed and prevented through improved...

Read

Topics:

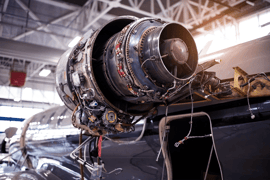

Maximize Manufacturing Excellence: Harness the Potential of Surface Quality Verification and Certification

In manufacturing, surfaces hold immense significance, and their value can be traced back to the inception of the Federal Aviation Administration (FAA) during the 20th century. The establishment of the FAA emerged as a response to mounting concerns surrounding quality control and the occurrence of...

Read

Topics:

Adhesive Bonding vs. Mechanical Fastening in Product Design: The Pros and Cons

When creating their next innovative product, designers, and manufacturers strive to achieve optimal performance while minimizing assembly and materials costs. In this pursuit, they often focus on optimizing material usage. In the quest to achieve optimization, it is uncommon for excess materials to...

Read

Topics:

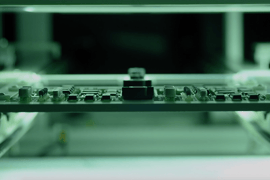

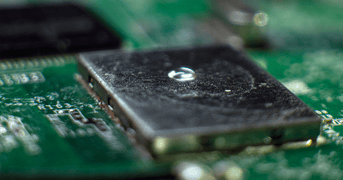

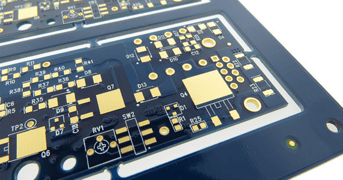

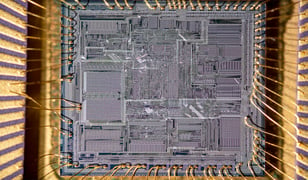

Ensuring Top-Quality Solder Joints on ENIG PCBs: Best Practices Unveiled

The field of printed circuit board (PCB) finishing and bonding methods has been growing and diversifying for decades. PCB design depends heavily on the use and environment of the electronic package, and those design decisions include what Surface Mount Technology (SMT) is employed. SMT involves the...

Read

Topics:

The Hidden Costs of Human Choices: Compromising Optimal Product Design and Manufacturing

In the realm of manufacturing and production, achieving strong and durable bonds is crucial for ensuring the quality and reliability of products. However, even with meticulous adherence to established processes, companies can sometimes face unexpected challenges that hinder their bonding...

Read

Topics:

How to Enhance Your Real-Time Production Monitoring of Material Surface Quality

The globalization of supply chains, diversification of team locations, outsourcing of essential organizational functions, and the digitalization of data and communication have made the world accessible to small and medium-sized manufacturers, challenging both large and small enterprises to respond...

Read

Topics:

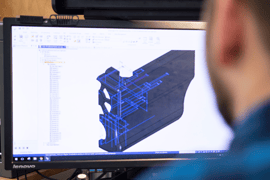

Fail Early, Fail Often: How Predictive Modeling Allows Teams To Correct Adhesion Failure In Product Development

What Does 'Fail Fast, Fail Often, Fail Intelligently' Even Mean? When it comes to business and innovation, making mistakes is inevitable. But instead of shying away from failure, we should embrace it as an opportunity to learn and grow. This concept is often referred to as "fail fast, fail often,...

Read

Topics:

How Contact Angle Measurements Can Spectacularly Reduce Scrap Rates Today

Last Updated March 2023 Predicting production outcomes in manufacturing relies on accurate data that calculates the variables that actually affect things like reliability, performance, and longevity of the product, like the soundness of bonds. There are countless tests to examine every conceivably...

Read

Topics:

Surface Analyst Technology Replaces the Old Language of Dyne Ink

For over a decade, manufacturers and suppliers have spoken the language of dyne when dealing with surface preparation and treatment verification. Because the process of dyne analysis requires users to interpret the way the ink spreads on a surface, it is highly subjective, making the language of...

Read

Topics:

How to Fix Common Causes of Adhesion Problems

Manufacturers often have a large blind spot regarding the causes of adhesion problems. This blind spot makes it impossible to solve these problems and generates frustration and loss rather than productivity and adhesion success. Taking the blinders off and taking on adhesion failure at its...

Read

Topics:

The Knowing Doing Gap: How to Avoid Widespread Adhesion Issues

At Brighton Science, we talk about surface intelligence and how it can be used to optimize manufacturing processes from the earliest stages. In response, organizations often say, “Great! That’s the key to solving, preventing, and controlling bonding issues, right? But do we have surface...

Read

Topics:

How Surface Intelligence Can Improve Your Return on Investment

“For every company, its competitiveness comes from its ability to assimilate knowledge and failure - which I tell my kids all the time - failure is an opportunity to learn and feedback is a gift. And if we take the 'quick fix' we take the learning off the table.” Andy Reeher, CEO, Brighton Science

Read

Topics:

Guess the Contact Angle: IPA Wiped Composite Material

This 'Guess the Contact Angle' video is the first of our next series of videos focusing on how contact angle changes when a composite surface is cleaned or treated in various ways. The contact angle featured in this demo is formed by a water droplet deposited using the handheld Surface Analyst on...

Read

Topics:

How To Keep Up With the Changing Landscape of Advanced Materials

There's a logical fallacy akin to a "what's good for one is good for all" mindset that is devastating when applied to surface treatment in adhesion processes. Polymers are rapidly being developed and synthesized for niche applications to push the limits of the current physical properties of...

Read

Topics:

The Top 5 Things Product Development Teams Need to Know About Real-World Manufacturing Challenges

Roles matter. Everyone within an organization is responsible for producing the most excellent and reliable new products in manufacturing. There is one downside to this - it can lead to siloed thinking. It can even discourage a common language between design teams and technicians dealing with...

Read

Topics:

Why Your Business Should Reject a Culture of 'Quick Fixes'

Quality gurus have long preached the importance of getting to the root of the problem. So why, then, when managers understand this so well, do organizations settle for the quick fix? It’s like taking a painkiller for a headache: the pain goes away for a while, but if there’s an underlying cause,...

Read

Topics:

Why a Surface Chemistry Input Should be Included in New Product Specifications

When development teams are looking to build a new product that includes a coating, bonding, painting, or sealing process, it's only natural to consider what kind of adhesive, coating, or paint will perform the best. While these selections are critical to the end product's success, development teams...

Read

Topics:

How Surface Quality Can Negatively Impact Product Launches

Manufacturing is a team effort. And as such, when an issue arises with the product (usually caught when scrap rates skyrocket and returns, recalls, and warranty claims make it clear something was missed), it can be difficult to precisely isolate the root cause of the problem.The interconnectedness...

Read

Topics:

Why It's Critical to Add a Cleanliness Specification to Your Vendor Compliance Program

Supply chain control ensures that the time, money, and labor put into a production process don’t go to waste. Managing what comes into the production process has a massive impact on how effective and efficient the production process will ultimately be. For companies dealing with bonding, coating,...

Read

Topics:

What Does Surface Intelligence Look Like in Action?

Surface condition is a significant driver of process and product reliability. It affects every part of the product life cycle, from development to launch, and its impact continues for as long as the product remains in service.

Read

Topics:

Top 6 Reasons Your Internal Organization Should Care About Surface Intelligence

Intelligence is a funny thing. On its face, it seems like the best way to gauge intelligence is to measure one's capacity for maximum knowledge intake through rote memorization of facts and figures. That sounds good, but it doesn't feel quite right. Because we all know knowledge that's just piled...

Read

Topics:

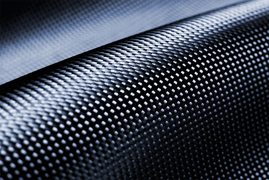

Importance of Adhesion & Composites in Lightweighting Cars

One of the most pressing questions on the minds of manufacturing engineers is how to take a load off. Lightweighting, or shedding pounds on assembled vehicles and machinery, is a critical puzzle in aerospace, marine, and, most acutely, automotive industries. In fact, with the pressure to optimize...

Read

Topics:

What are the Primary Causes of Chronic Adhesion Failures?

Adhesion problems tend to appear in the manufacturing process and then overstay their welcome. The chronic nature of so many adhesion issues is due to factors that many manufacturing companies are oblivious to. That’s not to fault the manufacturers. Until recently, there hasn’t been a reliable way...

Read

Topics:

Boost New Product Innovation Using Materials Science and Technology

Having the freedom to design and build to the limits of our imaginations is at the core of what makes us human. You must think outside the common practice to boost innovation and improve processes to accomplish this task.

Read

Topics:

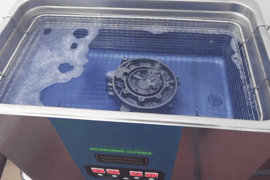

The Best Way to Qualify a Wash Method for Your Manufacturing Process

Parts washers are heavy-duty, hardworking machines that have become irreplaceable staples in automotive andmachined part manufacturing processes. As manufacturing processes have become more sophisticated, the industries using parts washers have expanded to includenot only industrial metals and...

Read

Topics:

4 Critical Questions for Assessing Product Development Risks

There are numerous obstacles to achieving and then maintaining a clean material surface. But there is one element that carries through the entire product lifecycle and can have a massive impact on the adhesion performance of the final product: TIME.

Read

Topics:

Why You Should Rethink Your Manufacturing Cleaning Process

In manufacturing, a final assembly is only as reliable as its constituent parts, the bonding or joining method used to hold them together, or the coating method used for corrosion protection and/or the final aesthetic touch. In order to guarantee the strength and successful performance of a...

Read

Topics:

Why You Should Implement a Surface Cleanliness Specification Using Contact Angle

When cleaning invisible contaminants from a surface, you may ask yourself, "How do I know when the surface is clean, or how clean, is clean enough?" These are common questions that product development teams ask when developing new products that require surfaces to be thoroughly cleaned in order to...

Read

Topics:

The Surface Analyst's™ Unique Method of Measuring Water Contact Angle

Fluid Deposition Style of Contact Angle Measurements Measuring the contact angle of a fluid on a surface provides a sensitive and accurate reading of surface energy. However, methods of depositing the droplet and measuring the contact angle vary. Common surface measurement instruments, such as ...

Read

Topics:

How to Measure Contact Angle on Convex and Concave Surfaces

Historically, accurately measuring contact angles on concave and convex surfaces has been a challenge. The typical method used to measure contact angle on these types of surfaces has been with abenchtop goniometer. The challenges arise from how goniometers measurecontact angle—from a horizontal...

Read

Topics:

Why Creating a Surface Intelligence Center of Excellence is Crucial for Manufacturing

As manufacturing becomes more complex and the globalization of supply chains increases, the need for a Surface Intelligence Center of Excellence grows. Such a center would compile data, training, and best practices from across the business to identify areas where further efficiency and quality...

Read

Topics:

Guess the Contact Angle: Plasma Treated Aluminum

So far in our Guess the Contact Angle Series, we have brought you three videos demonstrating how contact angle changes depending on the state of the material surface: Contact angle measurement on a piece of aged, 'as is' aluminum Contact angle measurement on aluminum after cleaning it with an IPA...

Read

Topics:

An Experts' Guide to Create a Surface Quality Specification

Various industries have different names for ways they change material surfaces during a production process. In medical fields and other industries dealing with high-reliability polymers, they’ll refer to the treatment of materials. In the automotive and machining sectors, the word used is often ...

Read

Topics:

How to Achieve Reliable Manufacturing by Controlling Surface Quality

When a material begins its journey through a manufacturing process, it becomes crucial to know and control everything that happens to that material as it makes its way down the line. There are two major factors to consider when understanding and controlling what happens to the surface of that...

Read

Topics:

How Surface Intelligence Enables Data-Driven Decision-Making & Advances Business Growth

Formula 1 teams know that you must incorporate a tried-and-true process into your workflow to perform at the highest level. They practice a defined, repeatable, measured, tested, and continuously improve their processes to ensure that their level of performance is constantly increasing. This can be...

Read

Topics:

What Is the Role of Surface Chemistry in Industry?

Manufacturing has become increasingly complex with the fusion of technologies that are blurring distinctions between the digital, physical, and biological worlds. Physical products and services have transformed significantly due to enhancements made possible by digital capabilities. New...

Read

Topics:

The Benefits of Benchmarking Surface Quality in Manufacturing

Certainty is the goal of every manufacturing process. Manufacturers must have total confidence that every aspect of their production process will go according to plan. The adhesion process needs to be controlled just like any other production operation, with accuracy and ongoing monitoring....

Read

Topics:

How to Bring Reliability to Complex Aspects of Material Engineering

Materials science and engineering influence our lives daily and open the door to new innovations in manufacturing. Each time you wear pair of shoes, scroll on your smart device or use a golf club, you are interacting with a product that was produced using materials, adhesives, and coatings that...

Read

Topics:

Does Your Organization Take A Holistic Approach to Innovation?

Innovation can be a scary thing. For companies built on order, predictability, and success, innovation can be unsettling. It can be messy, unpredictable, and prone to failure before producing a demonstrable payback. But innovation is vital. Without it, there can be no evolutionary growth or...

Read

Topics:

How to Design Products Using New Materials & Substrates with Confidence

Materials as technology is one of the most important fields in developmental science. As new materials are created and perfected, they proliferate and quickly spread to manufacturing centers around the world, spurring innovative product design. The rapid development of ceramic, sustainable...

Read

Topics:

How to Use Surface Intelligence Data to Build Smart Prototypes and Rapidly Pilot Manufacturing Lines

Since the Industrial Revolution, manufacturing has been evolving, periodically marked by significant, fundamental changes such as the introduction of mechanization, mass production through assembly lines, and computerization. Today, we are witnessing what experts call Industry 4.0 – a period when...

Read

Topics:

How to Get Help Finding the Root Cause of Adhesion Failure in Manufacturing

Adhesion, coating, and bonding problems tend to be persistent and resilient, causing frustration and leading to costly rework, recalls, scrap, production delays, and reputation loss, at worst. These problems often require more than manufacturers are currently equipped to handle on their own.

Read

Topics:

Guess the Contact Angle: Abraded Aluminum

So far, in our Guess the Contact Angle Series, we have brought you two videos: the first one shows the Surface Analyst taking a contact angle measurement on a piece of aged, 'as is' aluminum. The second video asks you to guess the contact angle after we took the same piece of aluminum but cleaned...

Read

Topics:

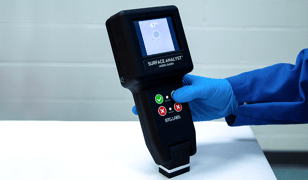

The Surface Analyst™ Instantly Measures Contact Angle to Determine the Potential Adhesive Strength of Bonds

A Handheld Solution for Verifying Surface Cleanliness The Surface Analyst™ is an innovative handheld solution for use in the lab and on the factory floor. It reduces waste, rework, and recalls when poorly prepared substrate surfaces lead to bonding, coating, sealing, painting, or printing failure.

Read

Topics:

Top Challenges Product Development Teams Experience When Bringing a Product Concept to Manufacturing

Modern product development is fraught with challenges due in large part to the sophistication and complexity of the various elements that go into a final product – everything from materials and surface geometries to coatings, bonding, and even staff skills and competencies. Pitfalls await even the...

Read

Topics:

BTG Labs Evolves Capabilities & Leadership to Become Brighton Science

Brighton Science Brings Unmatched Expertise to the Emerging Field of Surface Intelligence BTG Labs, a company that has spent the past 20 years solving critical adhesion issues and developing the world’s first surface inspection technology for leading manufacturers, has evolved its capabilities,...

Read

Topics:

Why Manufacturers Can’t Achieve Manufacturing Innovation Gains by Simply Purchasing Equipment

Innovation is a word you hear tossed around frequently in various industries. Many organizations pursue innovation relentlessly as the key to their success and to gaining or maintaining a competitive edge. But innovation can be elusive for organizations that don’t quite know how to support it. As a...

Read

Topics:

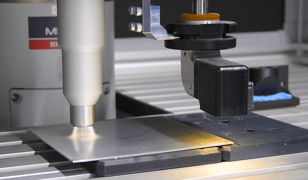

Does Surface Roughness Impact Contact Angle Measurements?

When measuring and quantifying surface energy, a common question arises: "Does surface roughness impact contact angle measurements obtained by the Surface Analyst?" In response, Surface Intelligence experts at Brighton Science launched a research project to determine whether contact angle...

Read

Topics:

Top 5 Trends in Products & Manufacturing Today

Change is perhaps the one absolute constant in manufacturing. Developments - in materials, processes, machinery, testing, products, markets, and thousands of other things affecting manufacturing companies - happen daily.

Read

Topics:

Guess the Contact Angle: IPA Wiped Aluminum

As part of the Guess the Contact Angle series, we have brought you a new video that highlights best practices when cleaning material surfaces with IPA wipes and we will ask you to "guess" the contact angle measurement after the surface has been cleaned. The contact angle featured in this demo is...

Read

Topics:

Contact Angle Measurements Guide Better, Data-Driven Quality Decisions

Deciding whether to reject a part or not based on a quality measurement always carries with it a finite risk: you could unknowingly decide that a perfectly good part is actually bad (a Type 1 error), or you might incorrectly conclude that a bad part is actually good (a Type 2 error). There is a...

Read

Topics:

Leveraging the Variability in Contact Angle Measurements to Improve Surface Quality and Process Control

Determining whether your material surface has been adequately cleaned or prepared for bonding, coating, sealing, painting, or printing requires the ability to objectively quantify the chemical and physical characteristics of the top few molecular layers: this is where all the action is. Water...

Read

Topics:

Can Contact Angle Quantitatively Measure Total Surface Energy?

In an article published in the Journal of Adhesion Science and Technology, "Water Contact Angle as a Quantitative Measure of Total Polyethylene Surface Energy" Materials Scientists from Brighton Science (formerly BTG Labs) explain the validity of water contact angle as a measurement for total ...

Read

Topics:

Eliminate Surface Engineering Challenges & Design with Freedom

Oftentimes, to boost innovation and improve processes, you have to think outside the common practice. You have to take the restraints off of creativity. Freedom to design and build to the limits of our imaginations is at the core of what makes us human.

Read

Topics:

How to Master Industrial Adhesion with Scientific Predictability

Manufacturers who produce products with surfaces that require paints, adhesives, or sealants face a challenge in determining the quality and reliability of the final product. The problem is often caused by the fact that most manufacturers don’t have complete control over three critical elements of...

Read

Topics:

Using Plasma for Surface Cleaning and Activation

This blog post is the first of a two-part series focusing on plasma. With the help of Rose Roberts, Ph.D., Senior Custom Applications and Materials Engineer, we will review plasma basics and discuss how plasma can be used for both cleaning and surface activation. We will also touch upon the...

Read

Topics:

Surface Measurements Help Coating and Plating Suppliers Guarantee Quality

Automotive supply chains are complex. Nearly 78 million vehicles were manufactured in 2020. Each vehicle may have upwards of 30,000 individual parts. Automotive original equipment manufacturers (OEMs) need to manage billions of parts annually. If any of these parts fail, vehicle performance is...

Read

Topics:

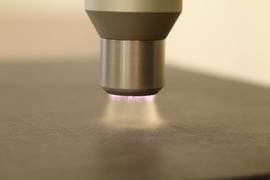

3 Things You Need to Know to Create Reliable Bonds With Laser Cleaning

Manufacturers are always looking to create stronger, more durable, reliable, and lightweight products in the automotive and aerospace sectors. In this pursuit, they’ve often upgraded and swapped out material systems for metal alloys with lower density, better temperature tolerance, and corrosion...

Read

Topics:

What Are Material Handling Best Practices to Keep Surfaces Clean?

Does your business, or your customer’s business, deal with adhesion – either in the form of bonding, coating, sealing, printing, or painting? Given that these processes may be occurring either upstream or downstream, does everyone in your organization share a common understanding and appreciation...

Read

Topics:

Guess the Contact Angle: Aged 'as is' Aluminum

In today’s blog post, we are going to have a bit of fun using video to learn more about contact angles. We will show you a contact angle and will ask you to “guess” the contact angle measurement. The contact angle featured in this demo is formed by a water droplet deposited on a piece of ‘as is’...

Read

Topics:

What to do When Your Contact Angle is out of Spec

Adhesive bonding can be used to create strong, reliable assemblies that perform extraordinarily well in the field. It is a deceptively sophisticated process frequently used in complex manufacturing environments. It is imperative to take a holistic view of each step in a multi-phased production...

Read

Topics:

Harnessing the Power of Water to Achieve Precise Results

Nature is miraculous. Living entities, be they plants, animals, marine life, or humans, can perform an amazing array of complex tasks. As scientists, inventors, and engineers, we take inspiration from any source that provides a good idea.

Read

Topics:

The Best Method of Measuring Contact Angles for Reliable Manufacturing Processes

"Materials Science" sounds niche and even a little peculiar, but no manufacturer is a stranger to the implications of material science principles for building reliable products. Materials react with one another. Material properties impact how these interactions occur. Accurately anticipating and...

Read

Topics:

Why Knowing Water Contact Angle is Important for Successful Adhesive Performance

Adhesives are an integral part of modern manufacturing, but choosing the right adhesive is only one part of the equation. It’s well known that you won’t get a reliable bond with an adhesive if you just slap the adhesive onto your material without doing anything to prepare that surface. What ISN’T...

Read

Topics:

10 Most Common Surface Quality Mistakes by Manufacturers

Manufacturers are constantly fighting against adhesion problems. Surfaces not sticking and adhesives not working is the daily reality facing manufacturers looking to make high-quality, reliable products. The daunting nature of the task of eliminating adhesion failure seems insurmountable and...

Read

Topics:

How Shoe Manufacturers Maintain Adhesion Quality Through Material Changes

There are many reasons why sneakerheads love the shoes they covet. Athletic shoes have become one of the most sought-after clothing items due to their aesthetic appeal and shoe manufacturers' ever-evolving material innovations.

Read

Topics:

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

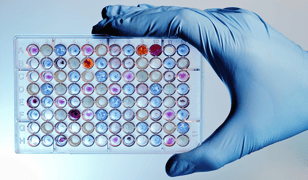

How to Reduce Medical Device Surface Testing Time and Subjectivity

Time is always of the essence for medical device manufacturers. When a medical breakthrough needs to make it to market, there is no time to waste. There is also no margin for error. Medical device manufacturers are always working with doctors and scientists to experiment with profound new...

Read

Topics:

Better Consumer Electronics Reliability: Coatings and Adhesives

In a recent study conducted by Instrumental, the top ten most common manufacturing defects were examined. The number one defect that manufacturers fight against is a deficiency in glue.

Read

Topics:

What is the Best Surface Quality Inspection for Smart Manufacturing?

Manufacturing processes can, on the surface, appear to be an amorphous web of convoluted conveyors and machinating machinery. But taking a closer look through the eyes of a quality engineer reveals that the process that leads to reliable products is, in fact, itself a series of decisions, each...

Read

Topics:

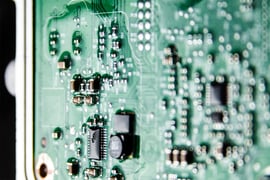

Reliable Wire Bonding Through Quality Data Collection for Industry 4.0

Wire bonding and sintering are critical processes involved in the manufacture of a majority of electronic devices. These processes are used to connect silicon chips, integrated circuits (ICs), and electrical components to their housings and boards.

Read

Topics:

What Medical Device Manufacturers Need From Surface Cleanliness Testing

Quality tests during medical device production need to check a lot of boxes for manufacturers. Testing must increase confidence in product reliability in order to be worthwhile to manufacturers. What’s more, that confidence needs to be measurable and reportable because companies cannot tolerate...

Read

Topics:

Where to Look to Achieve Operational Visibility in Manufacturing

Enterprise manufacturing operations comprise interlocking, overlapping, and critically interdependent processes. Each process in this symbiotic web consists of a series of steps that are only successful when the invisible details are unshrouded and subject to quantitative quality parameters.

Read

Topics:

Reliable and Efficient Manufacturing: Strategies You Can Use Now

Today, manufacturing requires a paradigm shift from reactionary whack-a-mole problem correction to taking a holistic approach. The mutually reliant elements of manufacturing are interwoven in both obvious and invisible ways. From supply chain communication to equipment dependability and from ...

Read

Topics:

Using Data to Improve Ink Adhesion to Polymer Film

One of the most frustrating aspects of experiencing a problem in manufacturing isn't necessarily the issue itself, but rather, it's the difficulty of accurately determining and communicating what the problem actually is.

Read

Topics:

How to Know if Hydrophilic Coatings on Medical Devices Provide the Necessary Comfort for Patients

Comfort is more than just a nice thing to hope for when it comes to medical devices like tubing, catheters and stents that are implanted into the human body. Comfort, in this instance, refers to the absence of pain. Having a piece of plastic or metal inserted into your body is never going to feel...

Read

Topics:

How to Control Surface Quality for Bonding Dissimilar Materials

We’ve mentioned many times in various articles that bonded material systems are becoming the norm for manufacturers in nearly every industry. In order to make finished products more efficient in terms of weight, cut material costs, accommodate more automated processes, lessen the need for repairs...

Read

Topics:

How to Bond Fiber Reinforced Plastics for Harsh Environments

Many manufacturers have a dual performance concern when their products are out there in the world being used in whatever capacity they were designed for. These parallel interests are: how to maintain the appearance and how to guarantee structural integrity through common usage of the products.

Read

Topics:

Coatings on Car Sensors and Why We Don’t Have Driverless Cars Yet

Our relationship with our vehicles may have changed in the past few months, with the idea of commuting to work looking more like a shuffle to the desk across the room rather than a drive to the office across town. However, cars have not dropped in prominence in our society. With health risks now...

Read

Topics:

The Best Way to Verify Medical Diagnostics Coatings

The biomedical industry runs on testing. Testing is at the heart of meeting extensive requirements to ensure healthcare practices and facilities are safe. A kind of testing that has been on all of our minds lately is the kind of testing that analyzes the presence of diseases. Often these tests...

Read

Topics:

Single vs Multi-fluid Contact Angle Techniques Part 2: Why one fluid is all you need for process control in manufacturing

This is part two of a two-part series explaining Brighton Science's approach to helping companies build reliability into their cleaning and adhesion processes through consultation and implementation of novel inspection equipment. These two articles are based on this technical paper written by Dr....

Read

Topics:

Single vs Multi-fluid Contact Angle Techniques Part 1: Surface energy and the attractions between substances

This is part one of a two-part series explaining the finer points of Brighton Science's approach to helping companies build reliability into their cleaning and adhesion processes through consultation and implementation of novel inspection equipment. These two articles are based on this technical...

Read

Topics:

Proposed ASTM Standard Will Ease the Pain of Manufacturers

An exciting development is taking place to make surface quality and cleanliness inspection technology more available to all manufacturers. We have collaborated with ASTM International and other stakeholders to craft a revision to establish a standard use of handheld goniometers in production...

Read

Topics:

Demystifying the Greatest Metal Brazing Process Challenges

When thinking about what manufacturing looks like, most people envision sparks flying, metal clanking, and fires blazing. This isn’t too far off the mark since metals were used to bond joints together to build larger, sturdier, and more stable structures before the first Industrial Revolution,...

Read

Topics:

Cleaning Strategies for Great Adhesion

Cleanliness in manufacturing gains avid devotees all the time. Once the importance of cleanliness is grasped, it’s nearly impossible to think about manufacturing processes without considering the pervasive impact cleanliness has on every aspect and feature of the process.

Read

Topics:

Why Surface Cleanliness is Crucial for Electronic PCBs

Defining “clean” is actually more complicated than it sounds. Cleanliness can be in the eye of the beholder (I mean, we all had a college roommate who swore they were tidy, but let’s be honest…), and it can also be calculated and precisely managed to the nth degree. In regard to PCB cleanliness for

Read

Topics:

The 3 Crucial Elements for High-Performance Adhesion in Manufacturing

Excellent adhesion relies on the manufacturer’s ability to understand and control three distinct yet interrelated elements. In manufacturing, adhesive bonding takes many forms, but the fundamental principles of adhesion are always the same. Even if the application is metal joint welding, Parylene...

Read

Topics:

New Solutions to Address Adhesion Failures in Manufacturing

In order to create predictable adhesion outcomes in manufacturing, precision is key. When thinking about the success of a bonding, printing, coating, sealing, painting or cleaning application, manufacturers need a new perspective. Manufacturers need an approach that considers the entire adhesion...

Read

Topics:

Best-practice Surface Preparation Processes for New Products

New Product Development is an essential component to the successful growth of companies that always challenge themselves to improve and innovate. Getting this design stage right is pivotal in that it sets in motion everything the product will be and how well it will perform.

Read

Topics:

How to Ensure a Manufacturing Surface is Clean Enough for Adhesion

Cleanliness and adhesion go hand-in-hand. If you’re looking for an adhesion process to be successful, you are also absolutely interested in cleaning the materials involved in the application. To get the most out of your cleaning operations, it’s imperative to know three things: What does clean...

Read

Topics:

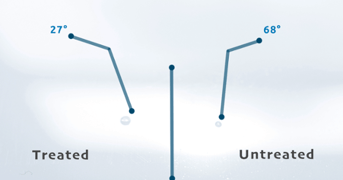

How to Know if a Manufacturing Surface is Treated or Untreated

In order to ensure successful bonding, coating, printing, painting, laminating or meet cleanliness standards in manufacturing, material surfaces must be manipulated. One such manipulation that gets surfaces ever closer to being ready for adhesion is surface treatment. There are many operations and...

Read

Topics:

How Surface Quality Devices Can Validate Adhesion Specs

Regulatory specifications in manufacturing exist to ensure that the highest quality, safest, and most useful products are created. These are devised internally through research and development testing to meet customer demands and through external regulatory bodies to protect consumers and public...

Read

Topics:

How to Transfer a Lab Surface Treatment Process to Production

Production processes don’t just materialize fully formed on the manufacturing floor. Procedures and operations go through a full research and development cycle, which can take years before they are integrated into the production line. This pre-production work includes strength, reliability, and...

Read

Topics:

4 Manufacturing Process Gaps that Create Adhesion Problems

Process gaps emerge in production processes any time manufacturers lack all the information they need to make decisions that will prevent or solve adhesion problems. Often, these gaps result from oversights; however, they can also exist and be difficult to detect because they only become obvious...

Read

Topics:

Can a Surface Science Lab Ensure Adhesion in Manufacturing?

Manufacturers utilize research and design laboratories all the time. To scale new products up to the production line, years of toiling in testing labs are done to ensure that everything goes off without a hitch once production starts.

Read

Topics:

Secrets to Predicting Adhesion Failures in Production

When adhesion failure becomes apparent in manufacturing processes, it can seem to come out of nowhere. Very often, there is no problem until suddenly there is. It feels unpredictable, unavoidable, and like the best solution is to either eat the loss it brings or just hope it goes away as quickly...

Read

Topics:

Why a Surface Quality Inspection Process Ensures Adhesion

Manufacturing processes that involve bonding, coating, sealing, printing, painting, laminating, or cleaning need a metric to measure the surface quality of the materials involved. Without such a metric, it is impossible to predict whether the adhesion process will be successful or if it's on the...

Read

Topics:

When it comes to low water contact angles, the Surface Analyst “means” business

The desktop goniometer is a widely-used and accepted method of obtaining surface energy measurements of materials in the lab setting. For those unfamiliar, the goniometer uses the “profile-view method,” with the water contact angle obtained optically as viewed from the side. This method effectively...

Read

Topics:

Tales from Brighton Science's Materials & Processing Lab

In the Brighton Science Materials and Processing Laboratory, magic happens. Or, at least, it seems that way. In the lab, our specialists see the unseen. They use expertise, specialized tools, and data to reveal the invisible.

Read

Topics:

Optimizing your Metal Performance with the Surface Analyst

Manufacturers who work with metal and are concerned with metal performance are all too familiar with the obstacles that come along with coating, painting, bonding, printing, or sealing it. While the uses of metal in manufacturing are countless and exist in numerous industries, the common...

Read

Topics:

Surface Treatment Processes: Flame Treatment

Flame treatment is a surface activation treatment process used to chemically modify a surface for better adhesion. This process is typically used on low-energy surfaces that can be difficult to adhere to, such as plastics and composites. The treatment is also very gentle, posing low risk to the...

Read

Topics:

CMH-17 Composite Materials Handbook: Validating Surface Preparation

Ongoing Advancements in the Field of Composite Materials Brighton Science (formerly BTG Labs) maintains an important connection to CMH-17, the Composite Materials Handbook. Brighton Science's special connection began in 2004 when Giles Dillingham, Founder and Chief Scientist, read that CMH-17...

Read

Topics:

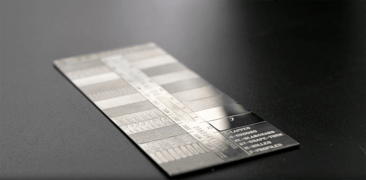

Gage Reproducibility and Repeatability (R&R) of the Surface Analyst™

Obtaining Quality and Consistency with the Surface Analyst Brighton Science's Surface Analyst™ uses a micro-liter of highly purified water to quantifiably measure contact angle. This objective measurement enables any user to obtain accurate results in either a pass/fail rating or a contact angle...

Read

Topics:

Common Surface Energy Tests: Dyne Inks

For years, manufacturers have implemented a conventional method of testing surface energy using a solution called dyne inks. Dyne ink, when applied to a surface, can reveal the surface's adhesion potential. But there's an inherent problem with the inks themselves...

Read

Topics:

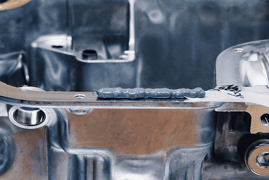

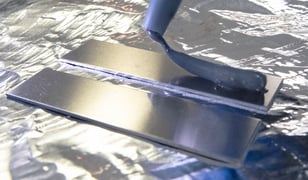

Ensuring Success for Automotive Formed-In-Place Gasket (FIPG) Sealing

Controlling Surface Condition in FIPG Application Increasingly, FIPG processes are replacing traditional gaskets for a variety of automotive applications, such as air filters, oil filters, door panels, and external engine parts. The advantages include cheaper material cost, higher throughput...

Read

Topics:

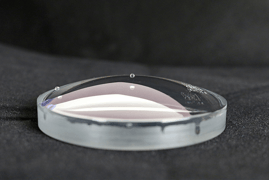

Contact Angle Measurements on Oxidized Polymer Surfaces Containing Water-Soluble Species

When Polymer Surfaces are Not Easily Accessible A collaboration between Brighton Science (formerly BTG Labs) and 3M scientists demonstrates that the Surface Analyst™ can provide receding contact angles. These contact angles precisely match the Wilhelmy-balance values, but in seconds instead of...

Read

Topics:

.png?width=372&height=180&name=adhesion-failure%20(2).png)

.jpg?width=372&height=180&name=metal-brazing-copper-component%20(reduced).jpg)