3 Things You Need to Control for Proper Adhesion

The “What,” “Way,” and “The Surface” Behind Reliable Surface Bonding In manufacturing environments where bonding, coating, printing, or sealing takes place, success is never accidental. Whether you’re assembling automotive interiors, medical devices, electronics, or aerospace composites, adhesion...

Read

Topics:

Posts by Topic

The Key to Stronger Composite Repairs? Measuring Surface Prep Before Bonding

Bond Repair: Making Surface Prep Measurable Bonding composites is never simple, but repairing them is an entirely different challenge. Unlike pristine manufacturing environments where parts are prepped and assembled under controlled conditions, repairs often happen in less-than-ideal circumstances:...

Read

Topics:

Why Water Contact Angle Became the Benchmark for Surface Quality

From Research Labs to Factory Floors In manufacturing, it’s often assumed that adhesion problems stem from the adhesive itself. But the truth is, many failures originate at the surface. Even the best adhesives, paints, or coatings can fail to perform if a surface isn't adequately prepared. Despite...

Read

Topics:

How Surface Measurements Help Medical Device Makers Avoid Delays

Medical Devices Face Unique Regulatory Pressures — and Surface Quality Plays a Bigger Role Than You Think Product reliability isn't optional in the medical device industry; it’s a regulatory requirement. Manufacturers must meet a growing number of global quality standards, from FDA regulations to ...

Read

Topics:

From Innovation to Standard: How Water Contact Angle Became the Surface Readiness Benchmark

A Common Language for an Uncommon Challenge One of the biggest barriers in global manufacturing is the lack of a shared language for surface quality. Engineering, operations, and suppliers often rely on guesswork or legacy tests.

Read

Topics:

Speed vs. Quality: How Manufacturing Sectors Balance Risk, Cost, and Innovation

In every manufacturing environment, there's one constant tension: how to move fast without breaking things. Whether you're building airplanes, cars, consumer electronics, or medical devices, the same tradeoff exists: production speed versus product quality.

Read

Topics:

Beyond Surface Prep: How Manufacturers Are Using Water Contact Angle to Control Adhesion Quality

Introduction Adhesion failures are among the most common yet preventable issues in composite bonding, coatings, and sealants. Whether in aerospace, automotive, or medical manufacturing, poor surface preparation can lead to structural weaknesses, warranty claims, and costly rework. But what if the...

Read

Topics:

Environmental Silicone: Detection, Control, and Impact on Adhesion in Manufacturing

Silicone contamination is a huge problem in many painting and bonding applications. It’s impossible to see, hard to remove, and it creeps in unseen like a ghost. Where the harm it can cause is recognized, businesses go to great lengths to clean surfaces and exclude potential sources of...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

Navigating the Solvent Switch: A Sustainable Future for Parts Cleaning

Manufacturers who use solvent-based industrial parts cleaning processes must find alternative methods. Solvent-based cleaning processes use chemicals that emit or release Volatile Organic Compounds (VOCs). These are coming under increased scrutiny due to their harmful effects on health and the...

Read

Topics:

Adhesive Bonding vs. Mechanical Fastening in Product Design: The Pros and Cons

When creating their next innovative product, designers, and manufacturers strive to achieve optimal performance while minimizing assembly and materials costs. In this pursuit, they often focus on optimizing material usage. In the quest to achieve optimization, it is uncommon for excess materials to...

Read

Topics:

Top Challenges Product Development Teams Experience When Bringing a Product Concept to Manufacturing

Modern product development is fraught with challenges due in large part to the sophistication and complexity of the various elements that go into a final product – everything from materials and surface geometries to coatings, bonding, and even staff skills and competencies. Pitfalls await even the...

Read

Topics:

How to Reduce Medical Device Surface Testing Time and Subjectivity

Time is always of the essence for medical device manufacturers. When a medical breakthrough needs to make it to market, there is no time to waste. There is also no margin for error. Medical device manufacturers are always working with doctors and scientists to experiment with profound new...

Read

Topics:

What Medical Device Manufacturers Need From Surface Cleanliness Testing

Quality tests during medical device production need to check a lot of boxes for manufacturers. Testing must increase confidence in product reliability in order to be worthwhile to manufacturers. What’s more, that confidence needs to be measurable and reportable because companies cannot tolerate...

Read

Topics:

Where to Look to Achieve Operational Visibility in Manufacturing

Enterprise manufacturing operations comprise interlocking, overlapping, and critically interdependent processes. Each process in this symbiotic web consists of a series of steps that are only successful when the invisible details are unshrouded and subject to quantitative quality parameters.

Read

Topics:

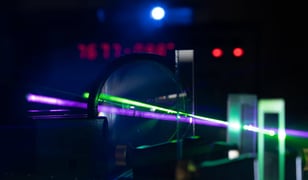

Surface Preparation for Reliable Optical Coatings in Photonics Manufacturing

Coatings are an indispensable part of manufacturing photonics. The coatings help determine the most basic functionality of the lenses they are applied to. How much light passes through, what happens to that light when it passes through the lens, does some light get absorbed, and are some spectral...

Read

Topics:

How to Know if Hydrophilic Coatings on Medical Devices Provide the Necessary Comfort for Patients

Comfort is more than just a nice thing to hope for when it comes to medical devices like tubing, catheters and stents that are implanted into the human body. Comfort, in this instance, refers to the absence of pain. Having a piece of plastic or metal inserted into your body is never going to feel...

Read

Topics:

Controlling Parts Washing Methods for Medical Components

Cleanliness is next to production standardization requirements for medical device manufacturers (as the old saying goes). Devices built to be inserted within the human body understandably need to meet the highest cleanliness standards. Companies in this industry have already known what many of us...

Read

Topics:

Verification vs. Validation for Medical Device Product Quality Assurance

Validation and verification are inextricable from product development and process design for the manufacturing of medical devices. To satisfy regulatory standards, reduce risk, create efficiencies, and ensure outcomes, manufacturers have ever-evolving validation and verification procedures. New...

Read

Topics:

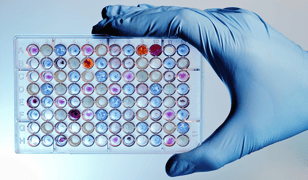

The Best Way to Verify Medical Diagnostics Coatings

The biomedical industry runs on testing. Testing is at the heart of meeting extensive requirements to ensure healthcare practices and facilities are safe. A kind of testing that has been on all of our minds lately is the kind of testing that analyzes the presence of diseases. Often these tests...

Read

Topics:

How to Protect Overmolded Connectors for Medical Devices

Protective coverings are part and parcel of our lives these days. For industries reliant upon electronic components and connectors, protective coverings in the form of polymeric over-molding encapsulation need to remain sealed and impervious to the environment.

Read

Topics:

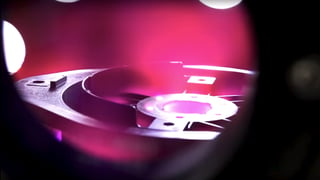

How to Get the Most Out of Your Vacuum Plasma Treatment

Vacuum plasma is the treatment method of record for many manufacturers. Not only because it is a legacy technology proven useful over many, many decades but because it can be particularly effective at creating chemically reactive surfaces of various geometries that need to be bonded, coated,...

Read

Topics:

Covid-19: Biological vs. Chemical Contamination in Manufacturing

Lately, the whole world has seen variations of the same conversation. Whether the discussion centers on N95 masks, toilet paper, hand sanitizer, disinfecting wipes, or what movies to watch while maintaining a safe social distance, the underlying concern is about cleanliness.

Read

Topics:

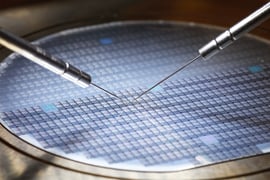

Don’t Forget the Surface of Microelectronics

It’s easy to be dazzled by the advancements in electronic and medical devices that are constantly being made and discovered, allowing manufacturers to work on increasingly micro levels. Smaller tech means greater efficiency and higher production rates, which can lead to lower prices and more...

Read

Topics:

.png?width=644&height=362&name=adhesion-failure%20(2).png)