How the Surface Intelligence Maturity Model Prevents Adhesion Failures and Reduces Manufacturing Costs

Executive Summary: Why You Need the Surface Intelligence Maturity Model Manufacturers across industries are losing millions to unseen surface issues that cause adhesion failures, recalls, and rework. Brighton Science’s new Surface Intelligence Maturity Model gives organizations a clear, five-stage...

Read

Topics:

Posts by Topic

Maximizing Composite Adhesion with Water Contact Angle Analysis: Why Surface Preparation Matters

Composite materials are essential in industries like aerospace, automotive, and medical devices because they offer a combination of strength and lightweight properties. But no matter how advanced these materials are, their performance relies on proper surface preparation. If a surface isn’t...

Read

Topics:

The Hidden Factor in Product Performance: Why the Top Few Molecular Levels of a Surface are Critical to Product Reliability

Manufactured and assembled products almost always require adhesion or cleaning steps—whether bonding, coating, painting, or printing—which makes the quality of those surfaces essential to the product's final performance. Contrary to conventional assumptions, surfaces are highly variable and...

Read

Topics:

Ensuring Gasket Reliability: The Critical Role of Surface Quality in Formed-in-Place Gasket Applications

Formed-in-place gaskets (FIPG) have revolutionized sealing solutions across industries that require high-reliability seals. While there are many types of gaskets, a FIPG is created from a specific method where a liquid sealant, typically applied by an automated dispensing system, is dispensed...

Read

Topics:

What Automotive Manufacturers Need to Know About Surface Analysis for Polymer Bonding and Coating

Polymers have taken center stage in automotive manufacturing. Their light weight, durability, and versatility make them ideal for many applications ranging from dashboards and door panels to bumper facias and fenders. However, as any product development or quality control professional will tell...

Read

Topics:

Gaining a Competitive Edge: The Power of Surface Analysis with Brighton Science

Every manufacturer that bonds, coats, paints, seals, or cleans needs objective surface measurement technology. It's the key to compressing lead times, reducing waste, and improving product consistency. Brighton Science has a versatile suite of solutions for surface analysis based on water contact...

Read

Topics:

5 New Ideas to Address Common Challenges Manufacturing Plant Managers Face

Leadership of a manufacturing plant demands exceptional skill. Plant managers navigate a dynamic landscape of ever-evolving responsibilities. Drawing on a decade of collaboration with hundreds of companies across countless operational challenges, we've identified key insights to help tackle these...

Read

Topics:

Is Inconsistent Surface Preparation Hurting Your Bottom Line? Here's the Fix.

In manufacturing, consistent and high-quality products are paramount to success. Surface preparation is critical in ensuring product performance, appearance, and durability. However, variations in surface preparation processes across an enterprise can lead to inconsistencies, inefficiencies, and...

Read

Topics:

Silicone Contamination: The Invisible Intruder to Quality in Assembly Line Production

Some manufacturers go to extraordinary lengths to eliminate the presence of silicone in their manufacturing facilities. Some manufacturers invest significant resources in cleaning procedures to eradicate any silicone contamination. These approaches can be revolutionized by the development of a...

Read

Topics:

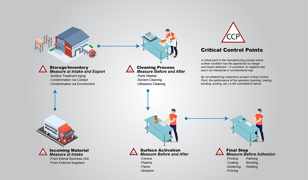

How to Control Your Adhesive Process: Find the Critical Control Points

In today's highly competitive manufacturing environment, controlling the adhesive process is vital to ensuring product quality, consistency, and efficiency. Understanding the Critical Control Points (CCPs) within the adhesive process is essential for maintaining control and achieving desired...

Read

Topics:

Identifying Adhesive Bond Failure Points in Manufacturing

One particular area that has proven to be a challenge in manufacturing is adhesion and surface quality. Research and development teams, product developers, and manufacturing operations frequently encounter difficulties with adhesion processes, such as coating or adhesion problems throughout the...

Read

Topics:

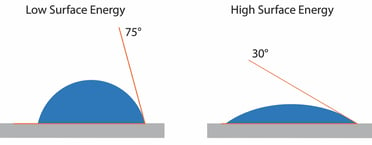

How Contact Angle Measurements Can Spectacularly Reduce Scrap Rates Today

Last Updated March 2023 Predicting production outcomes in manufacturing relies on accurate data that calculates the variables that actually affect things like reliability, performance, and longevity of the product, like the soundness of bonds. There are countless tests to examine every conceivably...

Read

Topics:

The Relationship Between Total Quality Management Systems and Sustainability

In the age of sustainability practices becoming more of the norm, there are a few ways in which your company can both abide by new regulatory standards concerning sustainable changes to the chemicals used and have a positive impact on your total quality management standards.

Read

Topics:

Easy Ways to Find Manufacturing Adhesion Failure Sources

When adhesion failure plagues a manufacturing process, it can be particularly disruptive. A production process may be humming along just fine, and then it suddenly becomes clear that a coating is uneven, or paint is chipping (when it wasn’t before), joints are weaker than they had been, or film is...

Read

Topics:

An Experts' Guide to Create a Surface Quality Specification

Various industries have different names for ways they change material surfaces during a production process. In medical fields and other industries dealing with high-reliability polymers, they’ll refer to the treatment of materials. In the automotive and machining sectors, the word used is often ...

Read

Topics:

What Is the Role of Surface Chemistry in Industry?

Manufacturing has become increasingly complex with the fusion of technologies that are blurring distinctions between the digital, physical, and biological worlds. Physical products and services have transformed significantly due to enhancements made possible by digital capabilities. New...

Read

Topics:

What Are Material Handling Best Practices to Keep Surfaces Clean?

Does your business, or your customer’s business, deal with adhesion – either in the form of bonding, coating, sealing, printing, or painting? Given that these processes may be occurring either upstream or downstream, does everyone in your organization share a common understanding and appreciation...

Read

Topics:

How to Measure Surface Tension

The attractive force of the molecules present at the surface of a liquid towards each other is called the surface tension of that liquid. It may seem like a little thing (and in terms of mass, it doesn’t really get much smaller than the top few molecular layers that make up the surface of a liquid...

Read

Topics:

What is the Difference Between Surface Tension and Surface Energy

Using adhesives in manufacturing is becoming increasingly common for building everything from massive machines to everyday tech devices. But companies' reliance on the science of adhesion to make sure their products work perfectly and look marvelous didn’t start there. In the centuries since the...

Read

Topics:

10 Most Common Surface Quality Mistakes by Manufacturers

Manufacturers are constantly fighting against adhesion problems. Surfaces not sticking and adhesives not working is the daily reality facing manufacturers looking to make high-quality, reliable products. The daunting nature of the task of eliminating adhesion failure seems insurmountable and...

Read

Topics:

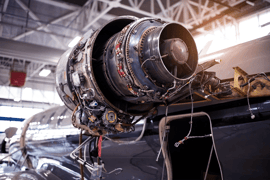

Surface Quality in Aircraft Sealing and Bonding for Repairs

When an aircraft is manufactured, every single portion of the plane or jet is designed to be able to be serviced and repaired for the next 20-30 years. Aircraft manufacturing OEMs are building aircraft with the expectation that extensive repairs will have to be done later down the road. This is an...

Read

Topics:

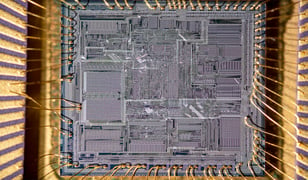

Reliable Wire Bonding Through Quality Data Collection for Industry 4.0

Wire bonding and sintering are critical processes involved in the manufacture of a majority of electronic devices. These processes are used to connect silicon chips, integrated circuits (ICs), and electrical components to their housings and boards.

Read

Topics:

Everything Breaks: What Reliability Means for Adhesively Bonded Products

The seemingly easy and obvious answer to the question implied in the title of this article is: reliability means no failures whatsoever forever and ever, amen. Sadly, it’s not quite so simple.

Read

Topics:

Ensuring the Durability of Oleophobic Coatings on Consumer Tech

Today, we're much more aware of the surfaces we touch and the potential unseen threats that linger on them. This focus on surface interaction isn't new for manufacturers, who've long considered how surfaces interact with our skin and the environment. Think about it – the simple act of touching...

Read

Topics:

How to Bond Fiber Reinforced Plastics for Harsh Environments

Many manufacturers have a dual performance concern when their products are out there in the world being used in whatever capacity they were designed for. These parallel interests are: how to maintain the appearance and how to guarantee structural integrity through common usage of the products.

Read

Topics:

7 Most Valuable Tips to Ensure Proper Adhesion in Production

Adhesion problems are an insidious concern to manufacturers in any industry with printing, painting, bonding, laminating, or coating applications. These problems settle into a production process, and they manifest in many different ways. An adhesion issue could look like a joint failure, uneven...

Read

Topics:

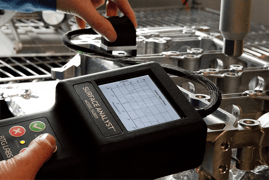

When it comes to low water contact angles, the Surface Analyst “means” business

The desktop goniometer is a widely-used and accepted method of obtaining surface energy measurements of materials in the lab setting. For those unfamiliar, the goniometer uses the “profile-view method,” with the water contact angle obtained optically as viewed from the side. This method effectively...

Read

Topics:

![Identifying Adhesive Bond Failure Points in Manufacturing [Key Considerations]](https://www.brighton-science.com/hs-fs/hubfs/images/blog-images/instron-adhesion-test-blog.jpg?width=372&height=180&name=instron-adhesion-test-blog.jpg)