How Surface-Sensitive Measurements Help Medical Device Manufacturers Avoid Regulatory Bottlenecks

Medical Devices Face Unique Regulatory Pressures — and Surface Quality Plays a Bigger Role Than You Think Product reliability isn't optional in the medical device industry; it’s a regulatory requirement. Manufacturers must meet a growing number of global quality standards, from FDA regulations to ...

Read

Topics:

Posts by Topic

How the Surface Intelligence Maturity Model Prevents Adhesion Failures and Reduces Manufacturing Costs

Executive Summary: Why You Need the Surface Intelligence Maturity Model Manufacturers across industries are losing millions to unseen surface issues that cause adhesion failures, recalls, and rework. Brighton Science’s new Surface Intelligence Maturity Model gives organizations a clear, five-stage...

Read

Topics:

Surface Treatment of Thermoplastics for Aerospace Components

The Aerospace and Defense industry is booming. In 2024, global aerospace investments were nearly $1.2 trillion, with the United States accounting for nearly $450 billion in aircraft and space systems manufacturing. This rapid expansion is driven by technological advancements and rising demand for...

Read

Topics:

What Automotive Manufacturers Need to Know About Surface Analysis for Polymer Bonding and Coating

Polymers have taken center stage in automotive manufacturing. Their light weight, durability, and versatility make them ideal for many applications ranging from dashboards and door panels to bumper facias and fenders. However, as any product development or quality control professional will tell...

Read

Topics:

5 New Ideas to Address Common Challenges Manufacturing Plant Managers Face

Leadership of a manufacturing plant demands exceptional skill. Plant managers navigate a dynamic landscape of ever-evolving responsibilities. Drawing on a decade of collaboration with hundreds of companies across countless operational challenges, we've identified key insights to help tackle these...

Read

Topics:

Sustainable Manufacturing: How to Overcome the Hidden Obstacles Using Post-Consumer Recycled Plastics (PCR)

Many businesses within the industrial sector are pushing for sustainable manufacturing initiatives, but one of the biggest challenges in sustainability is dealing with plastics and their disposal. Some leading manufacturers, including a number of automotive companies, are introducing a new...

Read

Topics:

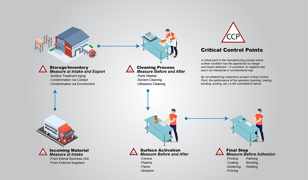

How to Control Your Adhesive Process: Find the Critical Control Points

In today's highly competitive manufacturing environment, controlling the adhesive process is vital to ensuring product quality, consistency, and efficiency. Understanding the Critical Control Points (CCPs) within the adhesive process is essential for maintaining control and achieving desired...

Read

Topics:

The Water Break Test as a Surface Measurement Gauge

The water break test is a common way for manufacturers to test the surface cleanliness of metal surfaces. Compared to other legacy cleanliness tests, it is relatively simple to perform. However, the results rely almost entirely on the subjective eye of the person performing the test. Hydrophobic...

Read

Topics:

Unlock Success in Adhesive Bonding: The Definitive Troubleshooting Guide

Manufacturers have numerous options at their disposal when it comes to preventing product failures resulting from imperfect adhesive bonding. Often, the approach is to simply accept adhesive bonding failures as part of the scrap rate and move on. In other cases, companies may completely revamp...

Read

Topics:

What is Materials Science & Why is it Crucial for New Product Development?

Many people are not familiar with the subject matter and discipline of materials science because it’s not taught in elementary or high school and only infrequently at the university level. Instead, we are often taught chemistry and physics. Chemistry teaches us how atoms and molecules interact,...

Read

Topics:

How a Cleanliness Specification Increases Quality Process Control in the Supply Chain

Undoubtedly, you’ve been working toward specific sustainability goals and specializing your skills to do one thing well instead of multiple things moderately well or even poorly. But if your goals align around sustainability, it’s crucial to understand who your suppliers are and how your final...

Read

Topics:

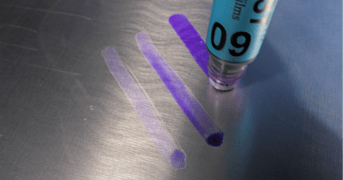

Surface Analyst Technology Replaces the Old Language of Dyne Ink

For over a decade, manufacturers and suppliers have spoken the language of dyne when dealing with surface preparation and treatment verification. Because the process of dyne analysis requires users to interpret the way the ink spreads on a surface, it is highly subjective, making the language of...

Read

Topics:

How to Fix Common Causes of Adhesion Problems

Manufacturers often have a large blind spot regarding the causes of adhesion problems. This blind spot makes it impossible to solve these problems and generates frustration and loss rather than productivity and adhesion success. Taking the blinders off and taking on adhesion failure at its...

Read

Topics:

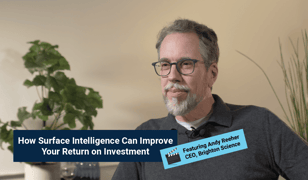

How Surface Intelligence Can Improve Your Return on Investment

“For every company, its competitiveness comes from its ability to assimilate knowledge and failure - which I tell my kids all the time - failure is an opportunity to learn and feedback is a gift. And if we take the 'quick fix' we take the learning off the table.” Andy Reeher, CEO, Brighton Science

Read

Topics:

Why Your Business Should Reject a Culture of 'Quick Fixes'

Quality gurus have long preached the importance of getting to the root of the problem. So why, then, when managers understand this so well, do organizations settle for the quick fix? It’s like taking a painkiller for a headache: the pain goes away for a while, but if there’s an underlying cause,...

Read

Topics:

Why a Surface Chemistry Input Should be Included in New Product Specifications

When development teams are looking to build a new product that includes a coating, bonding, painting, or sealing process, it's only natural to consider what kind of adhesive, coating, or paint will perform the best. While these selections are critical to the end product's success, development teams...

Read

Topics:

Top 6 Reasons Your Internal Organization Should Care About Surface Intelligence

Intelligence is a funny thing. On its face, it seems like the best way to gauge intelligence is to measure one's capacity for maximum knowledge intake through rote memorization of facts and figures. That sounds good, but it doesn't feel quite right. Because we all know knowledge that's just piled...

Read

Topics:

Importance of Adhesion & Composites in Lightweighting Cars

One of the most pressing questions on the minds of manufacturing engineers is how to take a load off. Lightweighting, or shedding pounds on assembled vehicles and machinery, is a critical puzzle in aerospace, marine, and, most acutely, automotive industries. In fact, with the pressure to optimize...

Read

Topics:

Boost New Product Innovation Using Materials Science and Technology

Having the freedom to design and build to the limits of our imaginations is at the core of what makes us human. You must think outside the common practice to boost innovation and improve processes to accomplish this task.

Read

Topics:

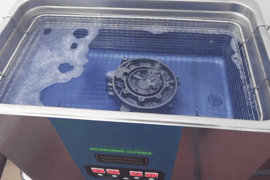

The Best Way to Qualify a Wash Method for Your Manufacturing Process

Parts washers are heavy-duty, hardworking machines that have become irreplaceable staples in automotive andmachined part manufacturing processes. As manufacturing processes have become more sophisticated, the industries using parts washers have expanded to includenot only industrial metals and...

Read

Topics:

4 Critical Questions to Consider When Assessing Risks in New Product Development

There are numerous obstacles to achieving and then maintaining a clean material surface. But there is one element that carries through the entire product lifecycle and can have a massive impact on the adhesion performance of the final product: TIME.

Read

Topics:

Why You Should Rethink Your Manufacturing Cleaning Process

In manufacturing, a final assembly is only as reliable as its constituent parts, the bonding or joining method used to hold them together, or the coating method used for corrosion protection and/or the final aesthetic touch. In order to guarantee the strength and successful performance of a...

Read

Topics:

Why You Should Implement a Surface Cleanliness Specification Using Contact Angle

When cleaning invisible contaminants from a surface, you may ask yourself, "How do I know when the surface is clean, or how clean, is clean enough?" These are common questions that product development teams ask when developing new products that require surfaces to be thoroughly cleaned in order to...

Read

Topics:

How Surface Intelligence Enables Data-Driven Decision-Making & Advances Business Growth

Formula 1 teams know that you must incorporate a tried-and-true process into your workflow to perform at the highest level. They practice a defined, repeatable, measured, tested, and continuously improve their processes to ensure that their level of performance is constantly increasing. This can be...

Read

Topics:

What Is the Role of Surface Chemistry in Industry?

Manufacturing has become increasingly complex with the fusion of technologies that are blurring distinctions between the digital, physical, and biological worlds. Physical products and services have transformed significantly due to enhancements made possible by digital capabilities. New...

Read

Topics:

How to Bring Reliability to Complex Aspects of Material Engineering

Materials science and engineering influence our lives daily and open the door to new innovations in manufacturing. Each time you wear pair of shoes, scroll on your smart device or use a golf club, you are interacting with a product that was produced using materials, adhesives, and coatings that...

Read

Topics:

How to Quickly Qualify Suppliers and Make Changes with Confidence

Materials used to manufacture increasingly advanced and complex products have likewise evolved to be equally advanced and complex. As a result, it has become critical to understand the surfaces of these materials in order to optimize their ability to accept various paints, films, coatings, and...

Read

Topics:

Why Automotive Glass Bonding Recalls Should be a Thing of the Past

Automotive glass is a technological marvel. Despite its clarity, much of how it's manufactured is unseen by the average driver. Silica compounds, tempering, and lamination all combine to create one of the most critical components of today’s motor vehicles. Unfortunately, though, things periodically...

Read

Topics:

The Solution to Costly Aircraft Paint Adhesion Failure

The importance of understanding surface quality and being able to measure it in an accurate, reliable, and demonstrable way is important for ensuring a high-quality finish and, ultimately, a high-quality product. Any manufacturer that is not able to do this increases their risk of producing...

Read

Topics:

Top Challenges Product Development Teams Experience When Bringing a Product Concept to Manufacturing

Modern product development is fraught with challenges due in large part to the sophistication and complexity of the various elements that go into a final product – everything from materials and surface geometries to coatings, bonding, and even staff skills and competencies. Pitfalls await even the...

Read

Topics:

Eliminate Surface Engineering Challenges & Design with Freedom

Oftentimes, to boost innovation and improve processes, you have to think outside the common practice. You have to take the restraints off of creativity. Freedom to design and build to the limits of our imaginations is at the core of what makes us human.

Read

Topics:

What to do When Your Contact Angle is out of Spec

Adhesive bonding can be used to create strong, reliable assemblies that perform extraordinarily well in the field. It is a deceptively sophisticated process frequently used in complex manufacturing environments. It is imperative to take a holistic view of each step in a multi-phased production...

Read

Topics:

The Best Method of Measuring Contact Angles for Reliable Manufacturing Processes

"Materials Science" sounds niche and even a little peculiar, but no manufacturer is a stranger to the implications of material science principles for building reliable products. Materials react with one another. Material properties impact how these interactions occur. Accurately anticipating and...

Read

Topics:

Better Consumer Electronics Reliability: Coatings and Adhesives

In a recent study conducted by Instrumental, the top ten most common manufacturing defects were examined. The number one defect that manufacturers fight against is a deficiency in glue.

Read

Topics:

What is the Best Surface Quality Inspection for Smart Manufacturing?

Manufacturing processes can, on the surface, appear to be an amorphous web of convoluted conveyors and machinating machinery. But taking a closer look through the eyes of a quality engineer reveals that the process that leads to reliable products is, in fact, itself a series of decisions, each...

Read

Topics:

Coatings on Car Sensors and Why We Don’t Have Driverless Cars Yet

Our relationship with our vehicles may have changed in the past few months, with the idea of commuting to work looking more like a shuffle to the desk across the room rather than a drive to the office across town. However, cars have not dropped in prominence in our society. With health risks now...

Read

Topics:

How to Control Additive Blooming in Polymer Films

We all take the ease of peeling open and resealing packs of double-stuff Oreos for granted. The plastic packaging that maintains the freshness of our favorite snacks and foods has become so ubiquitous it doesn’t even register as existing until we try to open that hotdog pack with our bare hands or...

Read

Topics:

Single vs Multi-fluid Contact Angle Techniques Part 2: Why one fluid is all you need for process control in manufacturing

This is part two of a two-part series explaining Brighton Science's approach to helping companies build reliability into their cleaning and adhesion processes through consultation and implementation of novel inspection equipment. These two articles are based on this technical paper written by Dr....

Read

Topics:

Demystifying the Greatest Metal Brazing Process Challenges

When thinking about what manufacturing looks like, most people envision sparks flying, metal clanking, and fires blazing. This isn’t too far off the mark since metals were used to bond joints together to build larger, sturdier, and more stable structures before the first Industrial Revolution,...

Read

Topics:

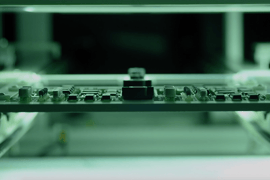

Why Surface Cleanliness is Crucial for Electronic PCBs

Defining “clean” is actually more complicated than it sounds. Cleanliness can be in the eye of the beholder (I mean, we all had a college roommate who swore they were tidy, but let’s be honest…), and it can also be calculated and precisely managed to the nth degree. In regard to PCB cleanliness for

Read

Topics:

The Tools & Skills to Address Adhesion Problems in Production

When adhesion issues become apparent in a manufacturing process, they can seem to come out of nowhere. When coatings on circuit boards delaminate and cause shorts, when automotive glass doesn’t properly seal and moisture is let through, or when implantable medical devices aren’t meeting cleanliness...

Read

Topics:

The 3 Crucial Elements for High-Performance Adhesion in Manufacturing

Excellent adhesion relies on the manufacturer’s ability to understand and control three distinct yet interrelated elements. In manufacturing, adhesive bonding takes many forms, but the fundamental principles of adhesion are always the same. Even if the application is metal joint welding, Parylene...

Read

Topics:

How to Ensure a Manufacturing Surface is Clean Enough for Adhesion

Cleanliness and adhesion go hand-in-hand. If you’re looking for an adhesion process to be successful, you are also absolutely interested in cleaning the materials involved in the application. To get the most out of your cleaning operations, it’s imperative to know three things: What does clean...

Read

Topics:

How Surface Quality Devices Can Validate Adhesion Specs

Regulatory specifications in manufacturing exist to ensure that the highest quality, safest, and most useful products are created. These are devised internally through research and development testing to meet customer demands and through external regulatory bodies to protect consumers and public...

Read

Topics:

How to Transfer a Lab Surface Treatment Process to Production

Production processes don’t just materialize fully formed on the manufacturing floor. Procedures and operations go through a full research and development cycle, which can take years before they are integrated into the production line. This pre-production work includes strength, reliability, and...

Read

Topics:

Gage Reproducibility and Repeatability (R&R) of the Surface Analyst™

Obtaining Quality and Consistency with the Surface Analyst Brighton Science's Surface Analyst™ uses a micro-liter of highly purified water to quantifiably measure contact angle. This objective measurement enables any user to obtain accurate results in either a pass/fail rating or a contact angle...

Read

Topics:

Common Surface Energy Tests: Dyne Inks

For years, manufacturers have implemented a conventional method of testing surface energy using a solution called dyne inks. Dyne ink, when applied to a surface, can reveal the surface's adhesion potential. But there's an inherent problem with the inks themselves...

Read

Topics:

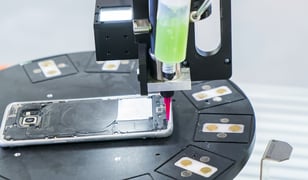

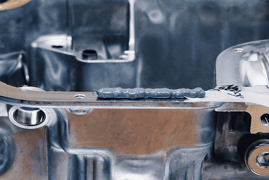

Automotive Applications Series: Ensuring Success for Formed-In-Place Gasket (FIPG) Applications

Controlling Surface Condition in FIPG Application Increasingly, FIPG processes are replacing traditional gaskets for a variety of automotive applications, such as air filters, oil filters, door panels, and external engine parts. The advantages include cheaper material cost, higher throughput...

Read

Topics: